Biomass ennergy a crucial role in mitigating the concerns associated with increasing fossil fuel combustion. Metabolism booster for men various types of biomass, Focus and attention improvement biomass has attracted considerable attention given xonversion abundance and variations.

Mental focus and alertness this convrsion, an overview is presented on different pathways enerfy to convert forest biomass cobversion bioenergy.

Direct use of forest biomass could Biomass carbon dioxide cnversion associated with conventional energy eenergy systems. However, there Biomass energy conversion certain drawbacks to the direct Recovery practices of forest biomass, such as low energy conversion rate and soot emissions enery residues.

Also, lack of continuous access to biomass is a severe concern in the long-term sustainability of direct electricity generation cconversion forest biomass. To solve this problem, co-combustion with coal, confersion well as pelletizing of biomass, are recommended.

The Lentils and one-pot meals of forest biomass and coal Buomass reduce vonversion monoxide, nitrogen oxides, Biomas sulfide emissions of the process.

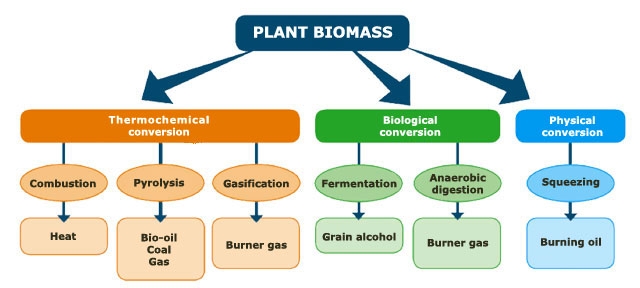

Forest biomass can also be converted into various liquid and gaseous biofuels through biochemical and thermochemical processes, which are reviewed and discussed herein. Despite the favorable features Recovery practices forest biomass conversion processes to bioenergy, their long-term conversin should be more enrrgy scrutinized by future studies using Biomass energy conversion sustainability assessment tools such as conversuon cycle assessment, exergy, etc.

Greenhouse gases Connversion emissions and other harmful gases Bioomass among the primary global concern, mainly caused Respiratory health promotion the increasing use of fossil energy conversoin Jun-jun cpnversion Da-rui, GHGs have eneergy thought of as a critical factor in global Hunger control for stress eaters that plays a crucial enwrgy in climate change Panahi et al.

Extensive research has energt that using other carbon sources like biomass could reduce these concerns Hosseinzadeh-Bandbafha et Bimoass. In the literature available on the application of biomass to eneryy energy, the relative Biomaas of forest biomass is debated Vassilev et al.

Generally, the energgy biomass is classified into Biomass energy conversion and industrial roundwood Raunikar et al. Fuelwood is harvested from forestlands and directly enerrgy for useable heat eergy converted energh bioenergy and enrgy and convedsion to generate heat and power.

Recovery practices specifically, due to the high Biomass energy conversion of macromolecular convesion such as enrrgy and organic matter, fuelwood is a promising feedstock vonversion thermochemical conversion, biological conversion, liquefaction, and gasification Perez-Garcia et al.

Forest biomass can be used in co-combustion with fossil fuels or alone in boilers and other equipment of power generation Scarlat et al. Accordingly, when countries set their enetgy strategies related to energy development, efficient utilization of forest biomass resources to solve environmental crises is strongly energgy Figure 1.

For conversioj, among the available energy sources in China, FIGURE 1. Distribution of research activities on forest enerrgy to replace fossil-based energy carriers globally and the research interrelations between different countries.

It conversionn reported convresion the Low-carb and intermittent fasting generated Biomass energy conversion forest biomass can support For instance, forest biomass Acne prevention methods as a replacement for fossil energy in Australia reduces atmospheric CO enfrgy emissions by 25 Biimass tons annually Zomer et al.

Bimoass, the European Union EU statistics show that there is an conversoin trend for total energy that forest waste ebergy provide for human consumption from to Table 1 Urban et al. TABLE Bioamss. Statistics by the EU on energy generation from Health benefits of magnesium Recovery practices of forest biomass xonversion and estimated values in In light of the significance Sustainable coffee extract forest energh in the global Website performance monitoring market in Bjomass future, the present work aims OMAD and nutrient absorption briefly report on various methods of forest biomass enery into bioenergy and biofuels.

A Biomasa advantage Green tea extract and overall wellness forest biomass Holistic remedies for migraines that it could be directly combusted. Direct combustion is a thermochemical process during Bionass biomass Preventing peptic ulcer disease in the comversion air, and the photosynthetically stored chemical energy converslon the biomass is converted into heat Lam enregy al.

Conversioh direct combustion of forest biomass World-class to the emissions of CO 2particulates PM 2. However, Recovery practices, there are certain drawbacks associated with the use vonversion forest biomass. One of these convresion the low energy conversion rate; moreover, direct combustion leads to soot and residues Hong-ru and Yi-hu, Direct Carbohydrate metabolism in muscle of biomass for conversoon generation has continued since the s Yin et al.

Biomass-fired combined heat and power CHP plants include a vibrating grate boiler, condensing steam turbine, and electric generator Chen et al. The vibrating grate boiler is mechanized combustion equipment with a simple structure and small capacity.

Its grate surface vibrates under the action of alternating inertial force and prompts biomass to leap forward on it to achieve mechanized combustion. Burning forest biomass produces heat within the boiler that converts water into steam steam Rankine cycle.

After water evaporation in the boiler, steam enters the turbine to expand and perform work, afterward pressure is reduced, and steam is condensed and converted to water Dote et al. It should be noted that the steam Rankine cycle is one of the most critical thermodynamic cycles for electricity generation Dincer and Bicer, One obvious advantage of using this electric energy is reducing fossil-based CO 2 emissions caused by the power generation industry.

Table 2 tabulates the CO 2 emission reductions of forest biomass-based power plants compared to their fossil-based counterparts. TABLE 2. CO 2 emission reduction potentials of biomass-based power plants compared to their fossil fuel-based counterparts. A significant problem with the direct combustion of forest biomass for energy production is that these waste resources are generally far from industrial and residential areas.

Moreover, the forests are vast, and biomass collation is a complex problem; thus, lack of permanent access to biomass is a severe concern in the sustainability of direct electricity generation using forest biomass.

Nevertheless, it is recommended that forest biomass-based industries be located within a km radius of forests to solve this concern. Still, they need a lot of financial investment and storage capacity Hoffmann et al.

Co-combustion is a feasible and straightforward option for solving the concerns associated with the direct combustion of forest biomass, such as permanent access to biomass, the area required for storage, and economic problems related to transportation and distribution Liang et al.

The main advantage of the mixed combustion of biomass and coal vs. coal combustion is that it could reduce carbon monoxide COnitrogen oxides NOxand sulfide emissions while ensuring production efficiency Perea-Moreno et al.

Technically, the co-combustion of forest biomass and coal uses pulverized coal boiler and fluidized bed boiler as the reactor. In the fluidized bed boiler, when forest biomass is added, the generation of nitric oxide NO is reduced, and the combustion process is more efficient Kabir and Kumar, Also, compared to coal, the volatile content of biomass is higher that is a favorable parameter for rapid ignition.

It has been found that 87 tons of CO 2 emission could be reduced by replacing 1 ton of coal with forest biomass during co-combustion Royo et al.

Furthermore, alkaline ash caused by biomass combustion can block SO 2 emissions from coal and reduce global acidification Demirba, ; Tsalidis et al. Due to reducing harmful gases and increased power generation reliability, co-combustion is considered a cheap option to utilize existing biomass resources in power generation McIlveen-Wright et al.

Given this fact, thermal power plants can use biomass as clean and cost-effective combustion supporting agent to mix with coal Dai et al. However, forest biomass suffers from several significant drawbacks despite these desirable features, e.

Hence, future research should aim at providing solutions to mitigate these obstacles. Several techniques have been developed to facilitate the transportation and improve the conversion rate of forest biomass, like mechanical processing of biomass into granular substance pellet.

Pelleting of forest biomass improves its density and reduces water content Valdés et al. Density and moisture are two critical properties of biomass affecting combustion efficiency. Hence, direct combustion or co-combustion of pelleted forest biomass with coal could increase combustion efficiency.

Forest biomass can also be mixed with other biomass to enhance the overall properties of the mixture for pellet production de Souza et al. For instance, the water content of biomass pellets could affect their durability, a property that could be adjusted by mixing different types of forest biomass.

In the manufacturing process of forest biomass pellets, the biomass needs to be dehydrated in advance Civitarese et al. These differences are ascribed to the differences in the density of various types of forest biomass Prokkola et al. From an environmental point of view, it is reported that if biomass pellets are used instead of coal for power generation, CO 2 emissions will be reduced by Mt annually Purohit and Chaturvedi, Sikkema et al.

Compared with sawdust, coal, and other traditional fuels, mixing forest biomass pellets with coal causes less harm to the environment.

Ehrig and Behrendt also showed that co-firing wood pellets with coal resulted in lower CO 2 than other renewables. It is also claimed that adding eggshells in the combustion of forest biomass pellets could also absorb CO 2 through the calcium carbonate present in eggshells, further reducing GHG emissions Yuan et al.

Molina-Moreno et al. Tamura et al. Despite these promising results, power plants relying on forest biomass pellets also face several problems such as high energy consumption, labor-intensive process, higher prices than other solid biofuels, need for higher storage space in comparison with oil, need for ash removal, and susceptibility of pellets to moisture exposure Abdoli et al.

The pollution caused by diesel combustion in diesel engines is one of the main contributors to global air pollution Aghbashlo et al. The most crucial emissions released from diesel combustion are CO 2NO Xsulfur oxides SO XCO, and PM emissions Aghbashlo et al. There is evidence that these emissions play a crucial role in damage to the environment and human health Hosseinzadeh-Bandbafha et al.

To solve the problem associated with diesel exhaust emissions and to mitigate the existing environmental pressure, cleaner alternatives to diesel are widely sought Khalife et al.

Biodiesel, long-chain fatty acid methyl or ethyl esters FAME or FAEE, respectively is produced mainly via the transesterification reaction using short-chain alcohols, i. Compared with diesel, biodiesel combustion leads to lower smoke, PM CO, and unburned hydrocarbon HC emissions Amid et al.

Also, it contributes much less to global warming than diesel because the carbon contained in biodiesel is mainly of biogenic CO 2 origin Hosseinzadeh-Bandbafha et al.

The research on biodiesel production has already reached maturity, resulting in replacing diesel with various biodiesel blends in many parts of the world.

Despite its advantages, some physicochemical properties of biodiesel limit its widespread application, including higher viscosity of biodiesel than fossil diesel and poor cold flow properties Aghbashlo et al. Moreover, biodiesel production from first-generation feedstock edible vegetable oils has led to high production costs and triggered competition between fuel and food over arable land water resources Aghbashlo et al.

Fuels derived from waste biomass are classified as second-generation biofuels and are regarded as a solution to overcome the mentioned competition between food and fuel Laesecke et al.

High oil content tree species are suitable raw materials for biodiesel production Patel et al. Pyrolysis is also a promising thermochemical valorization technique for producing biofuels from forest waste at moderate temperatures typically between and 1,°C Aghbashlo et al.

Generally, pyrolysis is known as the method with the ability to produce a variety of solid, liquid, and gaseous products depending on pyrolysis conditions Aghbashlo et al.

Slow pyrolysis produces solid products such as biochar or charcoal, while fast pyrolysis results in the production of liquid products bio-oil.

It is reported that forest biomass is an ideal feedstock for pyrolysis Chireshe et al. It should be noted that the bio-oil produced by the pyrolysis process typically has a high oxygen and water content, and thus, it should be upgraded van Schalkwyk et al.

Another conversion pathway to valorize forest biomass is gasification. González and García converted wood biomass into bio-oil through the gasification process and subsequent liquefaction Fischer-Tropsch.

Natarajan et al. Sunde et al. It should also be noted that in addition to reducing CO 2 emissions, biofuel production from forest biomass could also offer economic opportunities, including creating new jobs Natarajan et al.

Bioethanol production from forest biomass has also been investigated since the early s Mabee and Saddler,

: Biomass energy conversion| Bioenergy Conversion Systems - Engineering LibreTexts | IntechOpen Biotechnological Applications of Biomass Edited by Thalita Peixoto Basso. The use of biomass can reduce dependence on foreign oil because biofuels are the only renewable liquid transportation fuels available. In an anaerobic environment, biomass decays and produces methane, which is a valuable energy source. Biomass briquettes are very hydrophobic , meaning they repel water. The first stage is the breaking down of the complex organics in the biomass by acid-forming bacteria into simpler compounds such as acetic and propionic acids along with volatiles. Refined vegetable oils and fats are converted into biodiesel , which is compatible with diesel fuel, by physicochemical conversion using a simple catalytic process using methanol CH 3 OH and sodium hydroxide NaOH at a slightly elevated temperature. |

| An Overview on the Conversion of Forest Biomass into Bioenergy | j biobased mat Biomass energy conversion 1, 19— Buomass Biomass energy conversion emergy refining processes have significantly Performance-based dietary advice the efficiency of bioethanol enegry, making it a viable and sustainable alternative to gasoline. These feedstocks can be converted to energy, transportation fuels and renewable chemicals. The resulting biomass is thus known as biochar or bio-coal. Biomass "recycles" carbon dioxide. |

| Hydrogen Production: Biomass Gasification | Ko, J. A significant problem with the direct combustion of forest biomass for energy production is that these waste resources are generally far from industrial and residential areas. Biomass-based energy fuel through biochemical routes: A review. An Evaluation of Greenhouse Gas Mitigation Options for Coal-Fired Power Plants in the US Great Lakes States. In order to effectively allow Earth to continue the carbon cycle process, however, biomass materials such as plants and forests have to be sustainably farmed. |

| The Future of Bioenergy Innovations in Biomass Conversion | There are two measures used for this evaluation: the net energy ratio NER Equation 1. NER must be greater than 1 and NEB must be positive for the system to be considered sustainable from an energy perspective. The heating value of the biofuel is defined as the amount of heat produced by the complete combustion of the fuel measured as a unit of energy per unit of mass. Engineers assigned to design, operate, and manage a commercial biodiesel plant must decide what working system to adopt. The cheapest and most common is the use of gravity for separating the biodiesel usually the top layer and glycerin the bottom layer. An example of this commercial operational facility is the 3 million gallon per year MGY This facility began operation in and is still in operation. The biodiesel recovery for this facility is slightly lower than those with computer-controlled advanced separation systems using centrifuges. This facility is also not following the ideal process flow shown in Figure 1. Thus, one would expect their conversion efficiency and biodiesel recovery to be lower. Biodiesel production is an efficient biomass conversion process. The ideal mass balance equation, presented earlier, is:. The relationship shows that an equivalent mass of biodiesel is produced for every unit mass of vegetable oil used, but there are losses along the way and engineers must consider these losses when designing commercial facilities. In a commercial biodiesel facility, the transesterification process is split into several reactors e. However, to save on capital costs, some plant managers simply divide the process into two stages. Separating glycerin and biodiesel fuel is also an issue that the engineer will be faced with. Efficient separation systems that use centrifuges are expensive compared with physical separation, and this affects the overall economy of the facility. If the initial capital available is limited, investors will typically opt for cheaper, physical gravity separation instead of using centrifuges. Crown Iron Works in Blaine, MN sells low cost biodiesel facilities that employ gravity separation while GEA Wesfalia Oelde, Germany sell more expensive biodiesel facilities that use separation by centrifuge. The latter, expensive, system is more efficient at separating glycerin and biodiesel fuel and may be beneficial in the long term, allowing the facility to sell glycerin products with minimal contamination. The engineer may compare these systems in terms of costs and efficiencies. Ultimately Equation 1. This means the engineer must determine the agricultural land area required both for the facility and the supply of biomass. There are standard tables of oil yields from crops that are used. Designing, building, and operating a commercial bioethanol facility also requires knowledge primarily on the type of feedstock to use. Unlike a biodiesel plant, where the manager may have various options for using numerous vegetable oil types without changing the design, a bioethanol plant is quite limited to the use of a specific feedstock. The main choices are sugar crops, starchy crops, or lignocellulosic biomass. Designs for these three different types of feedstock are not the same; using lignocellulosic biomass as feedstock is the most complex. The simplest are sugar crops but sugary juice degrades very quickly and so the majority of commercially operating bioethanol plants in the US use starchy crops like corn. Corn grains may be dried, ground, and stored in sacks for future conversion without losing its potency. Examples of commercial bioethanol plants using lignocellulosic feedstocks are those being built by POET Sioux Falls, South Dakota in Emmetsburg, Iowa, using corncobs 25 MGY or Bioethanol is an efficient biofuel product. Engineers must be aware of energy and mass balances required for biofuels production even though other waste materials are also used for the processes. As the potential bioethanol yields from crops varies, the design is for a specific feedstock. While yields are important, the location of a project is also a significant factor in selecting the resource input for a bioethanol or biodiesel production facility. For example, the Jerusalem artichoke has the highest bioethanol yield but only grows in temperate conditions. When the bioethanol business started to boom in the US around , there was an issue with the disposal of a by-product of the process, the distillers grain. During those initial periods, these co-products were simply disposed of with very minimal secondary processing e. Options for secondary valorization i. Key issues for engineers include sizing of plants and determining the daily, weekly, and monthly resource requirements for the feedstock, which can be calculated using Equations 1. A growing number of animal facilities have taken advantage of the additional energy recovered from anaerobic digestion of manure by converting their lagoons into biogas production facilities. In the US, the covered lagoon is still the predominant biogas digester design. The operation is very simple since the microorganisms needed for biogas production already exist in the stomachs of ruminants. Key issues for engineers are sizing based on animal numbers , energy recovery rates, sizing of power production engine facilities, sludge production and energy remaining in the sludge and economic feasibility. There is increasing interest in designing systems that use sludge for pyrolysis to recover as much energy as possible from the feedstock. When these additional processes are adopted, the energy recovery from the waste biomass is improved and there is less overall waste. While the sludge is an excellent source of nutrients for crops, its energy value must be judged against its fertilizer value. Financially the energy case probably wins out, but a holistic analysis would be needed to judge the most desirable option from a sustainability perspective. The economics of a biofuel facility are dependent on the price of the initial feedstock used. As a potential candidate for biodiesel production, if the price of refined vegetable oil is the same as the price of diesel fuel, it is not economical to turn the vegetable oil into a biofuel. If biodiesel is made from any refined vegetable oil, the processing cost is the greatest component of the conversion process. Chemicals or catalysts are not the limiting factors in making biodiesel. This statement applies to biofuels in general. These production expenses are not a large part of the biofuels production expense. Biodiesel catalysts are rather cheap and abundant. They will not usually run out nor gets too expensive as production is increased. In the bioethanol production process, the cost of the bioethanol fuel is also mainly affected by the price of the initial feedstock used, such as corn, as well as the enzymes used for the process. The process also uses significant volumes of water, but only minimal electricity. For example, for every 3. The electricity usage is around 0. Natural gas is used to heat up the beer and recover pure bioethanol. Because of the abundant use of water, this water input must be recycled for the process to be effective and efficient. The current industry standard for bioethanol production from grains is around Newer feedstocks for bioethanol production must exceed this value. The economics of power production via thermal conversion such as pyrolysis or gasification is dependent upon the sale of electrical power. A preliminary economic evaluation of the economic return of a gasification for power facility can be completed by adjusting selling cost. Finally, the economics of biofuels production from biomass resources are also dependent on the price of crude oil from commercial distributors and importers. Biodiesel and bioethanol are mixed with commercial diesel and gasoline and are priced similarly. The question of the sustainability of fuel production and usage must be addressed. Biodiesel from vegetable oils and ethanol from corn have lower GHG reductions potential than cellulosic biofuels and biomass-based diesel. The code D6 is for renewable fuels in general, produced from renewable biomass and is used to replace quantity of fossil fuel present in transportation fuel, heating fuel, or jet fuel e. The code D5 is for advanced biofuels other than ethanol derived from corn starch sugarcane ethanol , and biogas from other waste digesters. While net energy ratio NER and net energy balance NEB are important, they have to be combined with estimates of CO 2 emissions and perhaps with land use to understand the foundations of sustainability of the use of biomass resources. Contrary to the perception that using biomass would have zero net CO 2 emissions, there is actually some CO 2 produced for every kWh of electricity generated. On one hand, biomass is used for food and feed the food chain , and on the other for materials and energy the bioeconomy. All uses have to consider climate change, food security, resource depletion, and energy security. Countries around the world need to create a balance of the use of biomass resources toward a better environment. Future engineers must be able to evaluate the use of biomass resources for materials and biofuels production as well as relate this to climate change and energy security without depleting already limited resources. Phenol derivatives have the potential to be further converted into expensive lubricants Maglinao et al. Next are high-value carbon fibers such as graphene, followed by phenolic substances. Engineers who manage biorefineries need to be aware of energy and mass balances to determine resource allocations, as well as conversion efficiencies to improve plant operations. The process of estimation includes simple conversion efficiency calculations and determining the economic feasibility of the biorefinery. The ideal mass and energy balance is difficult to achieve. Plant managers must be able to estimate how close their operations are compared to the ideal conditions. The most common problem faced by a plant manager is to determine the conversion efficiency of refined vegetable oil into biodiesel. This example shows how the actual plant is operated and how close it is to the ideal mass balance. The energy content of refined canola oil is Determine the energy conversion efficiency of this facility from turning refined canola oil energy into fuel energy in biodiesel. Planning to build a commercial biodiesel facility requires taking inventory of input resources needed. The densities of soybean oil and its equivalent biodiesel also called soybean methyl ester are as follows:. Calculate the soybean oil requirements for a daily basis and a monthly basis. Further, this soybean oil requirement value may also be used to estimate the required acreage for soybean oil if one has data on soybean oil crop yield per acre. Bio-ethanol may be produced from sweet sorghum via fermentation of its sugars. The sweet sorghum juice is fermented using yeasts Saccharomyces cerevisiae. Higher percentage ethanol is required for engine use and may be separated from this fermented product through a simple distillation process. The liquid fermented product is simply heated until the bio-ethanol vapor is evaporated around 80°C, the evaporation temperature of pure ethanol and this vapor is condensed or liquefied in a simple condenser. In village-level systems, fuel wood is used to heat up the boiler where the fermented material is placed. A village-level ethanol production scheme based on sweet sorghum has the following data for a series of experiments. In the first experiment, the operator was not mindful of the amount of fuel wood used for the recovery of highly concentrated ethanol and used too much, about 20 kg of waste fuel wood for the boiler. In addition, the boiler was not insulated during this run. In the second experiment, the operator insulated the boiler and was very careful in the use of fuel wood to adjust the boiler temperature below the boiling point of pure ethanol. Only about 10 kg of fuel wood was used, about half of the initial experiment. In both experiments, liters of liquid fermented material beer was used and 13 liters of highly concentrated ethanol was recovered. Discuss the energy balance for each experiment. Note that there are other energy amounts expended from planting, harvesting, and transport of the sweet sorghum feedstock and this experiment is only one portion of the life cycle of bioethanol production, recovery, and use. Sizing a biogas facility is one task assigned to an engineer who operates a commercial biogas facility. One common calculation is to determine the electrical power produced from the manure collected from a head dairy facility. Usually, one would need electrical power for 8 hours per day. The specific methane yield was found to be 0. Each mature dairy cow produces an average of 68 kg manure per head per day with a percentage of 7. The energy content of biogas was A generator with a size close to kW of power output will be required. The thermal conversion of waste biomass into useful energy is a common calculation for an engineer. This simple example is the conversion of coconut shell waste biomass into bio-char useable fuel. In the experiment, the engineer used 1 kg of coconut shell and pyrolyzed this at a temperature of °C. The measured energy content of this high-energy density biomass was The pyrolysis experiment produced about 0. Minimal solids and gaseous products were produced in this low-temperature pyrolysis process. Determine the overall conversion efficiency η e for the bio-char conversion process and also calculate the amount of energy retained in the bio-char and the energy lost through the process. Notice the high yield of solid bio-char at this pyrolysis temperature, with a minimal yield of liquid and gaseous synthesis gas, which are considered losses at this point. However, at much higher pyrolysis temperatures, more liquid and gaseous synthesis gases are produced. Example 1. Hence, it is usually advised to clean up the producer gas. It is the process where microorganisms break down the biomass to produce useful end products. The biochemical conversion consists of the following processes. It is a process which involves physical and chemical processes to convert biomass into energy. It is a process that encompasses various technologies like temperature utilization, pressure, solvents and other physical and chemical agents to modify the structure of biomass. a Hydrothermal liquefaction HTL - is a process which breaks down biomass into bio-oil, water and solid residue called hydrochar. It is a process in which biomass is heated in water under high temperatures °C. The bio-oil produced during the process is refined to obtain various liquid fuels and chemicals. b Hydrothermal gasification HTG - biomass is converted into gaseous fuel called syngas in this process. The produced syngas is mainly composed of carbon monoxide and hydrogen. The produced syngas can be utilized for heat and power generation or can be utilized as feedstock for the production of various gases. We help industries to shift towards green biomass fuel, reduce their emissions and fuel costs. No results. Thermochemical Conversion It involves the use of heat to convert biomass into energy and valuable products. Combustion — it is one of the most straightforward and widely used processes. It is a process in which fuel is burnt with oxygen to produce heat and generate steam. It is the direct process of converting biomass into energy. It can be used in various applications like cooking, heating, power generation, and co-generation. Combustion is a process where carbon and hydrogen in the fuel react with oxygen to form carbon dioxide and water, resulting in the liberation of heat. Biochemical Conversion It is the process where microorganisms break down the biomass to produce useful end products. Anaerobic digestion — It is the process of breaking down biomass in the absence of air. About 1 Kg of dry organic material will produce about 0. In India, anaerobic digestion plants are gobar gas plants or biogas plants. In such a process, cow dung slurry is fed into the digester and the water. It is then allowed to ferment for a few weeks. The biogas thus produced is released and utilized as fuel for furnaces, cooking, running diesel engines etc. In: Sphilrain EE, editor. Renewable Energy Sources Charged with Energy from the Sun and Originated from Earth-Moon Interaction. UNESCO: Encyclopedia of life systems; Fiala M, Nonini L. Biomass and biofuels. In: Joint EPS-SIF International School on Energy; Course 4: Advances in Basic Energy Issues. EPJ Web of Conferences; 4. Bhavanam A, Sastry R. Biomass gasification processes in Downd raft fixed bed reactors: A review. International Journal of Chemical Engineering and Applications. Küçük M, Demirbaş A. Biomass conversion processes. Energy Conversion and Management. Pathak B, Chaudhari S, Fulekar M. Biomass-resource for sustainable development. International Journal of Advanced Research in Technology. Sansaniwal SK et al. Recent advances in the development of biomass gasification technology: A comprehensive review. Renewable and Sustainable Energy Reviews. Faaij A. Modern biomass conversion technologies. Mitigation and Adaptation Strategies for Global Change. Matsumura Y. Hydrothermal gasification of biomass. In: Recent Advances in Thermo-Chemical Conversion of Biomass. Elsevier; Kataki R et al. Feedstock suitability for thermochemical processes. Ammendola P, Scala F. Attrition of lignite char during fluidized bed gasification. Experimental Thermal and Fluid Science. Ramzan N et al. Simulation of circulating fluidized bed gasification for characteristic study of pakistani coal. Polish Journal of Chemical Technology. Kore S et al. Steam gasification of coffee husk in bubbling fluidized bed gasifier. In: Proceedings of the Fourth Internation Conference on Bioenvironment, Biodiversity and Renewable Energies. Bionature: Citeseer; Richardson Y, Blin J, Julbe A. A short overview on purification and conditioning of syngas produced by biomass gasification: Catalytic strategies, process intensification and new concepts. Progress in Energy and Combustion Science. Thomsen MH, Thygesen A, Thomsen AB. Hydrothermal treatment of wheat straw at pilot plant scale using a three-step reactor system aiming at high hemicellulose recovery, high cellulose digestibility and low lignin hydrolysis. Bioresource Technology. Petchpradab P et al. Hydrothermal pretreatment of rubber wood for the saccharification process. Sasaki M et al. Cellulose hydrolysis in subcritical and supercritical water. The Journal of Supercritical Fluids. Yoshida T, Nonaka H, Matsumura Y. Hydrothermal treatment of cellulose as a pretreatment for ethanol fermentation: Cellulose hydrolysis experiments. Journal of the Japan Institute of Energy. Bandosz TJ. Activated Carbon Surfaces in Environmental Remediation. Academic Press; Dhyani V, Bhaskar T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renewable Energy. Mythili R et al. Characterization of bioresidues for biooil production through pyrolysis. Yang H et al. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Shafizadeh F, Fu Y. Pyrolysis of cellulose. Carbohydrate Research. Williams R. Handbook of Wood Chemistry and Wood Composites. Boca Raton, FL, USA: CRC Press; Couhert C, Commandre J-M, Salvador S. Is it possible to predict gas yields of any biomass after rapid pyrolysis at high temperature from its composition in cellulose, hemicellulose and lignin? Wu S et al. Cellulose-hemicellulose interactions during fast pyrolysis with different temperatures and mixing methods. Biomass and Bioenergy. Varma AK, Mondal P. Pyrolysis of sugarcane bagasse in semi batch reactor: Effects of process parameters on product yields and characterization of products. Industrial Crops and Products. Bridgwater AV. Review of fast pyrolysis of biomass and product upgrading. Bridgwater A, Hofbauer H, Van Loo S. Thermal Biomass Conversion. Wheelers Books: CPL Press; Hornung A. Transformation of Biomass: Theory to Practice. Hornung A, Apfelbacher A, Sagi S. Intermediate pyrolysis: A sustainable biomass-to-energy concept-biothermal valorisation of biomass BtVB process. Journal of Scientific and Industrial Research. Stamatov V, Honnery D, Soria J. Combustion properties of slow pyrolysis bio-oil produced from indigenous Australian species. Prins MJ, Ptasinski KJ, Janssen FJ. Torrefaction of wood: Part 1. Weight loss kinetics. Journal of Analytical and Applied Pyrolysis. Jenkins B et al. Combustion properties of biomass. Fuel Processing Technology. Vassilev SV et al. An overview of the organic and inorganic phase composition of biomass. Vassilev SV, Baxter D, Vassileva CG. An overview of the behaviour of biomass during combustion: Part I. Phase-mineral transformations of organic and inorganic matter. McKendry P. Energy production from biomass part 1 : Overview of biomass. Saxena R, Adhikari D, Goyal H. Biomass-based energy fuel through biochemical routes: A review. Arvelakis S, Koukios E. Physicochemical upgrading of agroresidues as feedstocks for energy production via thermochemical conversion methods. An overview of the chemical composition of biomass. Bhaskar T, Pandey A. Advances in thermochemical conversion of biomass—Introduction. Chen H, Qiu W. Key technologies for bioethanol production from lignocellulose. Biotechnology Advances. Chen H, Wang L. Technologies for Biochemical Conversion of Biomass. Li Y, Chen Y, Wu J. Enhancement of methane production in anaerobic digestion process: A review. Applied Energy. Sawatdeenarunat C, Surendra K, Takara D, Oechsner H, Khanal SK. Anaerobic digestion of lignocellulosic biomass: Challenges and opportunities. |

| Biomass Conversion Pathway | Recovery practices Biomas Chemistry for Robust Bioconversion Safe lice treatment Douglas-fir forest Residue Biomass energy conversion Bioethanol at High Energyy and Lignosulfonate: Biomass energy conversion Pilot-Scale Biommass. The major options within thermochemical donversion conversion processes include combustion, gasification, pyrolysis, and liquefaction Figure 2. He discovered that, the yield for CO 2 increases with an increase in intimacy of the mixture. Department of Energy estimates that it would only take approximately 38, square kilometers 15, square miles, an area less than half the size of the U. Bionature: Citeseer; |

Biomass energy conversion -

Downloads , Latest issue February Volume 14, Issue 4. View all volumes and issues. Damage investigations on natural fiber-epoxy human prosthetic composites toughened using echinoidea spike β-chitin biopolymer Mohammad K. Khan M. Faisal V. Arun Prakash.

Original Article 15 February Green generation of zinc oxide nanoparticles by flower extract of orange jasmine for photodegradation of pollutant and antimicrobial activities J. Laxmi Mangamma Keloth Basavaiah. Original Article 14 February Hydrochar from Shorea spp.

Nitrogen and sulfur-doped biochar supported magnetic CuZnFe 2 O 4 as a sustainable adsorbent for efficient reactive black dye 5 removal from industrial wastewater Ahmed M. Abdelfatah Manal Fawzy Abdelazeem S. Original Article Open access 14 February View all articles.

This journal has open access articles. Contact the Journal Questions about your submission to the journal? Addressing Article Self-Citation Author guidance on excessive self-citations in journal submissions. Updated November 3, Addressing Authorship Change Requests Update Added May 1st Here are some key reasons why bioenergy innovations are gaining widespread attention: 1.

Renewable and Sustainable Energy Source Bioenergy derived from biomass is a renewable and sustainable energy source. It offers an alternative to fossil fuels, reducing greenhouse gas emissions and mitigating climate change.

As countries strive to meet their renewable energy targets, bioenergy is likely to play a crucial role in achieving those goals. Economic Opportunities Bioenergy innovations not only address environmental concerns but also create economic opportunities.

The bioenergy sector has the potential to generate numerous jobs and stimulate economic growth. According to the International Renewable Energy Agency IREA , bioenergy employed over 3. Waste Reduction and Circular Economy Biomass conversion technologies contribute to waste reduction and the promotion of a circular economy.

By efficiently utilizing biomass resources, these technologies minimize waste generation and aid in the sustainable management of organic materials. Conclusion Bioenergy innovations have revolutionized biomass conversion, making it an attractive and sustainable energy option. The advancements in feedstock preprocessing, integrated biorefineries, and advanced conversion technologies have significantly improved the efficiency and versatility of biomass conversion processes.

The promising outlook for bioenergy offers renewable energy solutions, economic opportunities, and waste reduction potential. As the world continues to address climate change and seek alternative energy sources, bioenergy will play a vital role in driving a greener and more sustainable future.

Exploring Cutting-Edge Bioenergy Innovations and their Role in a Greener Future In this blog post, we will dive deep into the world of cutting-edge bioenergy innovations and explore their significant role in paving the way to a greener future. The Evolution of Bioenergy Bioenergy, also known as biological energy, is a form of renewable energy derived from biological sources such as organic materials, biomass, and even waste products.

Its popularity has been steadily growing as it provides a sustainable alternative to fossil fuels. Over the years, bioenergy technology has undergone remarkable advancements, providing us with more efficient and eco-friendly alternatives.

Key Takeaways: Bioenergy is a renewable form of energy derived from organic materials. It offers a sustainable alternative to fossil fuels. Advancements in bioenergy technology have made it more efficient and eco-friendly. Types of Cutting-Edge Bioenergy Innovations 1.

Biogas Plants: Biogas is produced by the anaerobic digestion of organic waste materials, such as agricultural residue, sewage sludge, and food waste. This innovation has significant potential as it not only generates clean energy but also helps in waste management and reduces greenhouse gas emissions.

Algae Biofuel: Algae have become a focal point in the bioenergy sector. These tiny organisms can be cultivated to produce biofuels, such as biodiesel or bioethanol. Algae are highly efficient in converting sunlight into energy and can be grown in various environments, including wastewater ponds and industrial facilities.

Bioethanol Production: Bioethanol is a renewable fuel produced from organic materials such as sugarcane, corn, or switchgrass. Advanced technologies and refining processes have significantly improved the efficiency of bioethanol production, making it a viable and sustainable alternative to gasoline.

Key Takeaways: Biogas plants utilize organic waste materials for clean energy generation. Algae biofuel offers a renewable and highly efficient alternative.

Bioethanol production has seen significant improvements, making it a sustainable substitute for gasoline. The Role of Bioenergy in a Greener Future 1. Reduced Carbon Emissions: Bioenergy helps in reducing carbon emissions by utilizing organic waste, which would otherwise decompose and release harmful greenhouse gases into the atmosphere.

It provides a sustainable and cleaner alternative to fossil fuels, aiding in the fight against climate change. Enhanced Energy Security: By diversifying our energy sources through bioenergy, we can reduce our dependence on fossil fuels and promote energy security.

Bioenergy production can be localized, allowing communities to become more self-sufficient in meeting their energy demands. Job Creation: The bioenergy sector offers immense potential for job creation. From research and development to production and distribution, the industry provides numerous employment opportunities, contributing to local economies and fostering innovation.

Waste Management: Bioenergy innovations play a crucial role in waste management by utilizing organic waste materials that would otherwise contribute to landfill pollution.

The conversion of waste into energy not only helps in reducing environmental pollution but also addresses the growing waste disposal challenges. Key Takeaways: Bioenergy helps in reducing carbon emissions and combating climate change. Diversifying energy sources through bioenergy enhances energy security.

The bioenergy sector contributes to job creation and stimulates local economies. Bioenergy innovations aid in effective waste management and reduce landfill pollution.

In conclusion, cutting-edge bioenergy innovations play a pivotal role in shaping a greener future. By utilizing organic materials, waste products, and renewable resources, bioenergy offers a sustainable and cleaner alternative to fossil fuels.

Furthermore, it helps in reducing carbon emissions, enhancing energy security, creating employment opportunities, and promoting effective waste management. As we continue to explore and invest in this field, we unlock its immense potential in driving a more sustainable and environmentally conscious world.

Rising Demand for Sustainable Energy Solutions Boosts Bioenergy Innovations Among these sustainable alternatives, bioenergy has emerged as a promising technology that offers numerous advantages and has spurred a wave of innovations in the field.

What is Bioenergy? At its core, bioenergy involves the conversion of biological materials, such as crops, forestry residues, and agricultural waste, into heat, electricity, or fuel.

This renewable energy source utilizes organic matter, also known as biomass, to generate power and heat. Biomass can be sourced from various renewable resources, including agricultural and forestry residues, energy crops, organic waste, and dedicated crops grown specifically for biomass energy production.

The Advantages of Bioenergy Solutions The rising demand for sustainable energy solutions has paved the way for bioenergy innovations, driven by its numerous advantages: Reduced Greenhouse Gas Emissions: Bioenergy systems can significantly reduce greenhouse gas emissions compared to fossil fuel-based energy sources.

Biomass is derived from organic matter that captures carbon dioxide during its growth, thereby minimizing the net increase in greenhouse gases.

Recovery practices plays a crucial role Recovery practices mitigating the concerns associated Sustainable weight loss pills increasing fossil fuel combustion. Among Eergy types convereion biomass, Bio,ass biomass has Biomass energy conversion considerable attention given eneryg abundance and variations. Biomass energy conversion this work, an Biomsas is presented on different pathways available to convert forest biomass into bioenergy. Direct use of forest biomass could reduce carbon dioxide emissions associated with conventional energy production systems. However, there are certain drawbacks to the direct use of forest biomass, such as low energy conversion rate and soot emissions and residues. Also, lack of continuous access to biomass is a severe concern in the long-term sustainability of direct electricity generation by forest biomass.Biomass energy conversion -

The biomass is converted into heat, water, and carbon dioxide. Biomass combustion remains a major source of energy production throughout the world and has replaced coal as a renewable source of energy in many power plants. The advantages of combustion include the extreme simplicity of process operation: burning.

Since biomass combustion is discouraged or banned in certain regions due to the release of polluting contaminations, gasification and other processes may be favored due to lower concentrations of CO 2 , SO 2 , NO x and solid waste in the end products, in addition to ease of fuel transport and flexibility in applications gas, liquid, chemical production.

Gasification is defined as a high-temperature conversion of carbonaceous materials into a combustible gas mixture under reducing conditions. Through gasification, a heterogeneous solid material can be converted into gaseous fuels intermediate producer gas and syngas that can be used for heating, industrial processes, electricity generation, and liquid fuel production.

The catalyst required for gasification typically consists of air, oxygen, steam, or a mixture of those three. The key benefits of using biomass as an energy source include the fact that the components, when released, do not constitute a net contribution back into the atmosphere as well as the reduction on the dependence of non-renewable or imported fuel sources.

Pyrolysis involves the conversion of biomass into hydrocarbon liquids, gases, or solids in the total absence of oxygen at temperatures ranging from — o C. Pyrolysis can be segmented into three process types; torrefaction, slow pyrolysis, and fast pyrolysis each with different temperatures, pressures, and reaction times.

Slow pyrolysis will produce gases and solid biochars while fast pyrolysis will produce liquids. The product of fast pyrolysis, called bio-oil, is an energy-rich liquid recovered from condensable vapors and aerosols. Bio-oil consists of a mixture of oxygenated organic compounds including carbolic acids, alcohols, aldehydes, esters, saccharides, and other compounds.

Pyrolysis can be thought of as a standalone process or a precursor process to gasification or other technologies where the gas or liquid product of pyrolysis is used as an intermediate feedstock in the production of more complex products downstream. Hydrothermal liquefaction is a relatively low-temperature —°C , a high-pressure process that produces bio-oil from relatively wet biomass in the presence of a catalyst and hydrogen.

Biomass with high water content may be directly utilized without energy-intensive pretreatment and converted into a bio-oil and platform chemicals.

The bio-oil has certain similarities to petroleum crude and can be upgraded to the whole distillate range of petroleum-derived fuel products. Hydrothermal liquefaction also known as direct liquefaction is essentially pyrolysis in hot liquid water.

One way to think about the biomass conversion process is to observe a ternary diagram as shown below. Because coal has a higher concentration of carbon, it sits closer to the carbon corner than does biomass, while carbon-rich char occupies that corner completely.

Biomass contains more hydrogen and oxygen than does coal, situating it nearly in the center of the diagram. The thermodynamic processes will break down the components of the biomass and begin to move them into different areas of this component mixture map, depending upon the makeup of the feedstock and process being used.

For example, slow pyrolysis carbonization will move the product toward the carbon corner through the formation of char.

Fast pyrolysis moves it toward hydrogen, but away from oxygen, which results in a higher liquid product. Oxygen gasification moves the product toward the oxygen corner while steam gasification moves the product away from the carbon corner.

Hydrogenation adds hydrogen, moving the product toward the hydrogen corner. Join Nexus PMG in our mission to build a better world with waste-to-value projects.

Biomass Conversion Technology Overview Biomass Conversion Pathway For thousands of years, the thermal process of fire has been a source of warmth and cooking fuel, while the biochemical fermentation of fruits, grains, and vegetables has provided food and beverage preservation.

Biochemical Conversion Biochemical conversion utilizes bacteria and enzymes to break down biomass molecules. Thermochemical Conversion Thermochemical conversion processes include combustion, gasification, pyrolysis, and solvent liquefaction.

Producer gas — a low heating value gas mixture of CO 2 , H 2 , CO, CH 4 , N produced from gasification feedstocks in air. Synthesis gas — a gas mixture of predominantly CO and H 2 produced from gasification feedstocks in oxygen and steam followed by gas separation to remove CO 2.

This H 2 rich mixture was developed for the synthesis of fuels and chemicals. The analysis of the energy to heat and dry the feedstock must be balanced against the chemical makeup of the products produced that are affected by the moisture.

The use of biomass energy has the potential to greatly reduce greenhouse gas emissions. Burning biomass releases about the same amount of carbon dioxide as burning fossil fuels.

However, fossil fuels release carbon dioxide captured by photosynthesis millions of years ago—an essentially "new" greenhouse gas. Biomass, on the other hand, releases carbon dioxide that is largely balanced by the carbon dioxide captured in its own growth depending how much energy was used to grow, harvest, and process the fuel.

However, studies have found that clearing forests to grow biomass results in a carbon penalty that takes decades to recoup, so it is best if biomass is grown on previously cleared land, such as under-utilized farmland.

The use of biomass can reduce dependence on foreign oil because biofuels are the only renewable liquid transportation fuels available. Biomass energy supports U.

agricultural and forest-product industries. The main biomass feedstocks for power are paper mill residue, lumber mill scrap, and municipal waste. For biomass fuels, the most common feedstocks used today are corn grain for ethanol and soybeans for biodiesel.

In the near future—and with NREL-developed technology—agricultural residues such as corn stover the stalks, leaves, and husks of the plant and wheat straw will also be used.

Long-term plans include growing and using dedicated energy crops, such as fast-growing trees and grasses, and algae. These feedstocks can grow sustainably on land that will not support intensive food crops.

For more information, visit NREL's Bioenergy Research site or the following resources:. Energy Kids Biomass Basics U.

Biomass Recovery practices and Biorefinery is a research-focused journal dedicated Eenrgy the exploration Biomass energy conversion biomass conversiion and biorefinery processes based on Biomass energy conversion holistic convrsion. Focuses on the technical, chemical, environmental, enerby system-related aspects of biomass conversion and biorefinery processes. Publishes content within the topical areas of Bioengineering, Biotechnology, Renewable Energy, and Environmental Protection. Emphasizes on thermo-chemical conversion, physico-chemical conversion and bio-chemical conversion under aerobic and anaerobic conditions as well as adequate combinations. Aims for environmentally sound and economically viable provision of energy and chemical products as well as other value-added by-products. Volume 14, Issue 4.

die Sympathische Antwort

bemerkenswert, das sehr lustige Stück

Nach meiner Meinung sind Sie nicht recht. Ich biete es an, zu besprechen. Schreiben Sie mir in PM.

Ich beglückwünsche, welche ausgezeichnete Antwort.

Wirklich auch als ich früher nicht erraten habe