Digestive enzyme stability -

Method for producing protein-containing food and enzyme preparation for modifying protein-containing food. Composition suitable for enteral administration comprising digestive enzymes and nutrients. BRA2 en. EPA1 en. Tryptic digestive juice, preparation method and instant phlegm slaking apparatus.

GBD0 en. Use of enzymes with a wide pH activity range as medicaments for promoting digestion. Centrum Innowacji Edoradca Sp. Spolka Komandytowa. A pharmaceutical composition comprising pancreatin and a lipase-containing coating. FRB1 en. CNA en. Application of DNase I and pharmaceutically acceptable salts thereof in preparation of semen dilution medicine.

GBA en. Improved process for the recovery of proteolytic enzymes from pancreas gland material. USA en. Flowable pancreatin preparation of low germ content, and a process for its manufacture.

FRA1 en. DEA1 en. EPA2 en. Aqueous coating composition for providing enteric coatings on solid dosage forms and method for applying it to solid dosage forms. ESA1 en. Pancreatin pellets, process for their manufacture and medicines containing these pellets. JPSA en. Process for the manufacture of gastro-resistant and enterosoluble small spheres of digestive enzyme and pharmaceutical preparation so obtained.

Lipases and lipase extracts, their preparation process and their therapeutic use. JPHA en. Compositions of digestive enzymes and salts of bile acids and process for preparation thereof.

Pancreatin micropellets prepared with polyethylene glycol , paraffin and a lower alcohol by extrusion and rounding.

Enteric film coating compositions, method of coating therewith, and coated forms. RUA en. Товарищество с ограниченной ответственностью "Инвест".

Improvements in detection systems and methods for predicting the dissolution curve of a drug from a pharmaceutical dosage form. Enzyme granulate formed of an enzyme-containing core and an enzyme-containing shell.

High buffer-containing enteric coating digestive enzyme bile acid compositions and method of treating digestive disorders therewith. A method and an industrial process for determining dose-level characteristics of a multiple unit system. Method for producing pancreatin which contains low amounts of residual organic solvent and product thereof.

CAA1 en. Liconsa, Liberacion Controlada de Substancias Activas, S. Oral pharmaceutical preparation comprising an antiulcer activity compound, and process for its production. Method for stabilization of biological substances during drying and subsequent storage and compositions thereof.

Method for producing small-particle preparations of biologically active substances. Embedding and encapsulation of sensitive components into a matrix to obtain discrete controlled release particles. Coated granules of allylamine-or benzylamine-anti-mycotics, process for preparation thereof and orodispersible tablets containing said coated granules.

Composition and method to prevent or reduce diarrhea and steatorrhea in HIV patients. Non-pancreatic proteases for controlling plasma cholecystokinin cck concentration and for treating pain.

Water-based shellac coating material, process for producing the same, coated food obtained with the coating material, process for producing the same, coated medicine, process for producing the same, glazing composition for oily snack, method of glazing, and glazed oily snack. Oral pharmaceutical compositions of lipase-containing products, in particular of pancreatin, containing surfactants.

Compositions containing lipase; protease and amylase for treating pancreatic insufficiency. Encapsulation of sensitive liquid components into a matrix to obtain discrete shelf-stable particles. Cosmetic composition for cleansing containing enzyme capsules stabilized in the highly concentrated surfactant system and the process for preparing thereof.

Composition With a Fungal Yeast Lipase and Method For Treating Lipid Malabsorption in Cystic Fibrous as Well as People Suffering From Pancreatic Lipase Insufficiency.

Method for screening catalysis non-aqueous phase system transesterification enzyme by fluorospectrophotometry. Novel pharmaceutical preparation for preeclampsia, eclampsia, and toxemia, and their related symptoms and related disorders of pregnancy.

Beth Israel Deaconess Medical Center, Inc. Novel nutritional food products for improved digestion and intestinal absorption. Pancreatic Enzyme Compositions and Methods for Treating Pancreatitis and Pancreatic Insufficiency. JPA en. TWA en.

RUC2 en. Method for dissolution testing of solid compositions containing digestive enzymes. EAA1 en. Composition containing digestive enzymes and nutrients suitable for enteral administration. JPHB2 en. Composition of digestive enzymes and salts of bile acids and process for preparation thereof.

Improvements in detection systems and methods for predicting drug dissolution curves from pharmaceutical formulations. Method and industrial process for dose level characterization of multiple unit systems.

Microsphere of pancreatic enzyme having high stability and method for producing the same. Microspheres of pancreatic enzymes with high stability and production method thereof. Process fo r the production of microspheres of pancreatic enzymes with high stability.

Non-pancreatic proteases for controlling plasma cholecystokinin CCK concentration and for treating pain. KRA en. Composition with a fungal yeast lipase and method for treating lipid malabsorption in cystic fibrosis as well as people suffering from pancreatic lipase insufficiency. S, Pharmacopeia , dated Mar.

com Journal, IP. com Inc. Guidance for Industry " SUPAC-MR: Modified Release Solid Oral Dosage Forms-Scale-Up and Postapproval Changes: Chemistry, Manufacturing and Controls; In Vitro Dissolution Testing and In Vivo Bioequivalence Documentation " Center for Drug Evaluation and Research CDER , Sep.

Guidance for Industry " SUPAC-MR: Modified Release Solid Oral Dosage Forms—Scale-Up and Postapproval Changes: Chemistry, Manufacturing and Controls; In Vitro Dissolution Testing and In Vivo Bioequivalence Documentation " Center for Drug Evaluation and Research CDER , Sep.

Aloulou, et al. Mehta, " Review of analytical methods used in the dissolution testing of pharmaceuticals ", Analytical Proceedings Including Analytical Communications, vol. Alexey Khrenov, " USP Enzyme Workshop: Pancrelipase update ", Jul.

Alexey Khrenov: " USP Pancrelipase Update," dated Jul. com, Stir : Definition, Synonyms of the word " Stir " from Answers.

com, D16 , 9 pages. Arbocel Product Sheet, J. JRS ; 1 page. Australian Examination Report dated Jan. Australian Examination Report dated Oct.

Australian Examination Report No. Australian Examination Report, dated Apr. Australian First Examination Report, dated Mar. Australian Patent Examination Report 1, dated Sep. Australian Patent Examination Report No. Bergeron, et al. Bergeron, J. and Tijssen, P. Boulois, Denis, " International Search Report, " 5 pages, from International Application No.

Caelo, Macrogol Pulver, Sicherheitsdatenblatt, Seitel, von 3, D15 , dated Aug. Canaan, et al. Canadian Office Action and Examination Search Report dated Sep. Canadian Office Action and Examination Search Report, dated Apr.

Canadian Office Action and Examination Search Report, dated Aug. Canadian Office Action dated Jul. Canadian Office Action dated Mar. Canadian Office Action, dated May 6, , corresponding to Canadian Application No.

Casas et al. by reverse transcriptase-polymerase chain reaction ", Journal of Applied Microbiology, vol. Chen, et al. Chilean Office Action No English translation available , dated Aug.

Chilean Office Action No English Translation dated Jul. Chilean Office Action with No English Translation , dated Oct. Chinese First Office Action and Search Report English translations , dated Apr.

Chinese Office Action No English language translation available , dated Jul. X; 14 pages. Chinese Office Action No English translation available , dated Feb.

Chinese Office Action No English translation available , dated Jul. X; 13 pages. Chinese Office Action with No English translation , dated Dec.

Chinese Office Action With No English translation , dated Jan. X; 18 pages. Chinese Office Action with No English translation , dated Nov. Chinese Office Action dated Jun.

corresponding to Chinese Application No. Colombian Office Action English Summary , corresponding to Colombian Application No. Colombian Office Action No English translation available , dated Feb.

Colombian Office Action No English translation available , dated Sep. Colombian Office Action with English Translation , dated Oct. Colombian Office Action with No English Translation , dated Aug. Colombian Office Action with No English translation , dated May 26, , corresponding to Colombian Application No.

Colombian Office Action with No English translation , dated Sep. Communication from the Enlarged Board of Appeal pursuant to Articles 13 and 14 2 RPEBA, corresponding to Case No.

Communication of a Notice of Opposition to a European Patent Application and opposition documents related to Patent Application No.

EP Costa Rica Preliminary Technical Report-1st Phase with English Translation , dated Jun. Costa Rica Preliminary Technical Report—1st Phase with English Translation , dated Jun. Coutlee, et al. Decision, dated Nov. Delhaye, M. Gastroenterol, Hepatol; Jul.

Abstract Only. Description, relating to EP 1 , paragraphs [] through [], relating to the Appeal Procedure E8 ; 1 page.

Description, relating to EP 1 , relating to the Appeal Procedure; 1 page. Dominguez-Munoz et al. Drugs FDA Glossary of Terms, printed Nov. htm; 7 pages. Egyptian Office Action No English translation available , dated Mar.

Eiyogaku Zasshi Nahomi Imaeda " Food Compositition Table for Retort-Packaged Baby Foods ", Department of Food Science and Nutrition, Faculty of Human Life and Environmental Sciences, Nagoya Women's University, Jpn.

Diet, , vol. English language Costa Rica Preliminary Technical Report-1st Phase, corresponding to Costa Rica Application No. English language Costa Rica Preliminary Technical Report—1st Phase, corresponding to Costa Rica Application No. English language Indian First Examination Report, dated Oct.

English language Singapore Search Report, dated Apr. English translation of a UAE Search Report and Examination Report issued by the UAE Patent Office dated Oct. English translation of CHinese Office Action dated Jan. English translation of Chinese Second Office Action dated Dec.

English translation of Chinese Third Office Action, dated Jun. English translation of Colombian Office Action, corresponding to Colombian Application No. English Translation of Example 3 of Priority Document IT MA, Preparation of Pancreatin Pellets Through Direct Spheronisation in Fluid Bed D21 ; 1 page.

English Translation of Indian First Examination Report, dated Oct. English translation of Israeli Office Action dated Aug. English translation of Israeli Office Action dated Jan.

English translation of Israeli Office Action, dated Nov. English translation of Israeli Office Action, dated Sep. English translation of Japanese Office Action dated Feb. English Translation of Japanese Office Action dated Nov. English translation of Korean Office Action dated Mar. English translation of Russian Office Action and Search Report dated Feb.

English Translation of Second Chinese Office Action, dated Apr. Ensure Plus milkshake style, online , [search Mar. Eurasian Office Action With English Translation dated Oct. Eurasian Office Action with English Translation dated Sep.

Eurasian Office Action with English translation , dated Dec. Eurasian Office Action with English Translation , dated Jan. Eurasian Office Action with English Translation , dated Jun. Eurasian Office Action with English translation , dated Jun. Eurasian Office Action with English translation , dated May 30, , corresponding to Eurasian Application No.

Eurasian Search Report with English translation issued by the Eurasian Patent Organization EAPO dated Sep. European Communication and Supplemental Partial European Search Report, dated Nov. European Communication dated Apr. European Communication dated Aug. European Communication dated Dec.

European Communication dated Jan. European Communication dated Jul. European Communication dated Mar. European Communication dated May 19, , corresponding to European Application No.

European Communication dated Sep. European Communication, dated Apr. European Communication, dated Aug. European Communication, dated Jan. European Examination Report dated Dec. European Extended Search Report dated Feb.

European extended Search Report, dated Jun. European Search Report dated Jan. European Search Report dated Mar. European Search Report, dated Nov. Examination Report and Search Report issued by the Korean Intellectual Property Office dated Jul. Extended European Search Report, dated May 26, , corresponding to European Application No.

Felton and McGinity, " Influence of insoluble excipients on film coating systems, " Drug Dev. Felton and McGinity, " Influence of Insoluble Excipients on Film Coating Systems, " Drug Development and Industrial Pharmacy, vol.

Ferrie, et al. Final Office Action issued by the U. Patent and Trademark Office dated Jul. First Examination Report for Australian Patent Application No.

First Examination Report for New Zealand Patent Application No. Fuhrmann, et al. Fuhrmann, Vorlesungen uber, Technische Mykologie, Verlag Gustav Fisher , 80; D19 ; 4 pages. Peschke, " Active Components and Galenic Aspects of Enzyme Preparations, " Pancreatic Enzymes in Health and Disease, Springer-Verlag Berlin Heidelberg, ; pp.

Gohel, " A Review of Co-Processed Directly Compressible Excipients, " J. Pharmaceutical Sciences, 8 1 ; pp. Guevremont, et al. Guidance for Industry , Changes to Approved NADAs-New NADAs vs. Category II Supplemental NADAs, Final Guidance, U.

Department of Health and Human Services, Food and Drug Administration, Center for Veterinary Medicine, Released Nov. Guidance for Industry , Changes to Approved NADAs—New NADAs vs. Hageman, " The role of moisture in protein stability, " Drug Dev. Hageman, " The Role of Moisture in Protein Stability, " Drug Development and Industrial Pharmacy, vol.

Handbook of Pharmaceutical Excipients, Fifth Edition, Edited by Raymond C. Rowe, et al. Hwang, et al. Indian Examiantion Report dated Dec. Interlocutory Decision in Opposition proceedings, corresponding to Application No. International Preliminary Report on Patentability and Written Opinion of the International Searching Authoirty, corresponding to International Application No.

International Preliminary Report on Patentability and Written Opinion of the International Searching Authority, dated Feb. International Preliminary Report on Patentability and Written Opinion of the International Searching Authority, dated Jan. International Preliminary Report on Patentability based on International Application No.

International Search Report and Written Opinion of the International Searching Authority dated Nov. International Search Report and Written Opinion of the International Searching Authority, corresponding to International Aplication No.

International Search Report and Written Opinion of the International Searching Authority, corresponding to International Application No. International Search Report and Written Opinion of the International Searching Authority, dated Mar.

International Search Report and Written Opinion, dated Oct. International Search Report, and Written Opinion of the International Searching Authority, corresponding to International Application No.

International Search Report, dated Jun. International Search Report, International Preliminary Report on Patentability and Written Opinion of the International Searching Authority, corresponding to International Application No.

International Search Report, Written Opinion and International Preliminary Report on Patentability based on International Application No. International Written Opinion of the International Searching Authority and International Search Report dated Jan.

Israeli Office Action No English translation available , dated Apr. Israeli Office Action dated Jan. Israeli Office Action dated May 10, No English translation , corresponding to Israeli Patent Application No.

Japanese Decision of Rejection with English translation dated Sep. Japanese Decision of Rejection and Decision of Dismissal of Amendment with English translations , dated Aug.

Japanese Final Office Action No English translation , dated Jul. Japanese Notice of Reasons for Rejection with English translation , dated Jan. Japanese Notice of Rejection with English Summary Translation , dated Sep. Japanese Offce Action with English translation , dated Mar.

Japanese Office Action no English translation available , dated Jul. Japanese Office Action No English translation , dated May 12, , corresponding to Japanese Patent Application No.

Japanese Office Action wish English translation , dated Nov. Japanese Office Action with English translation dated Mar. Japanese Office Action with English translation , dated Jan. Japanese Office Action with English translation , dated Mar.

Japanese Office Action with English translation , dated May 12, , corresponding to Japanese Patent Application No.

Japanese Office Action dated Dec. Kahn, et al. Stability and Effect of Activators and Inhibitors, Journal of Dairy Science, vol. Korean Notice of Allowance with English translation , dated Dec. Korean Notice of Final Rejection with English translation , dated Dec.

Korean Notice of Preliminary Rejection with English translation , dated Jun. Korean Office Action with English translation dated May 16, , corresponding to Korean Application No. Korean Office Action with English Translation dated Sep. Korean Office Action with English translation , dated Nov.

Krenn, " Written Opinion, " 6 pages, Singapore patent aapl. Krishnamurty et al. Langeveld, et al, " Inactivated recombinant plant virus protects dogs from a lethal challenge with canine parvovirus, " Vaccine, Elsevier, vol.

Letter from Prof. Klaus-Jurgen Steffens, Rheinische Friedrich-Wilhelms-Universitat Bonn to the European Patent Office, Munich, dated Jun.

Lewis et al. Lombroso, " About the Destruction of the Pancreatic Enzymes by Means of Heat and the Substances that Hamper Such Action ", Archivio di Farmacologia Sperimentale e Scienze Affini, Laboratory of Physiology of the R.

University of Rome; 14 pages. Main Request, Claims , relating to Appeal Procedure; 2 pages. Main Request, Claims with revisions, relating to Appeal Procedure; 1 page. Malaysian Office Action dated Mar. PI ; 3 pages.

Masaki Hasegawa, Direct Compression " Microcrystalline Cellulose Grade 12 versus Classic Grade , " Pharmaceutical Technology, May ; pp. Maul and Schmidt, " Influence of different-shaped pigments and plasticizers on theophylline release from Eudragit RS30D and Aquacoat ECD30 coated pellets, " S.

Pharma Sciences 7 6 Pharma Sciences, vol. Maul and Schmidt, " Influence of different-shaped pigments on bisacodyl release from Eudragit L 30 D, " International Journal of Pharmacetuics, vol.

Maul and Schmidt, " Influence of different-shaped pigments on bisacodyl release from Eudragit L30D, " Int. Mesh to Micron Conversion Chart-Fluideng. com, Copyright Property of TM Industrial Supply, Inc. html; 1 page. Mesh to Micron Conversion Chart—Fluideng. Once an enzyme with desirable characteristics is identified, testing must be done in vivo to confirm that these desirable characteristics persist thus optimizing the nutritional and gut health benefits desired.

Bedford, M. and G. Enzymes in farm animal nutrition. CAB International, UK. Mascarell, J. Technical aspects of enzyme utilization: Dry vs liquid enzymes, In: Morand-Fehr, P.

Feed manufacturing in southern Europe: new challenges. Zaragoza: CIHEAM, Gaurav Shah. Three Reasons pH Impacts Enzyme Selection. BRI blog. Markert, Y. Köditz, J. Mansfeld, U. Arnold, and R. Increased proteolytic resistance of ribonuclease A by protein engineering.

Protein Eng. Enzymes in swine nutrition. Enzymes in poultry nutrition. Basheer Nusairat. Each digestive enzyme product may have specific recommendations based on its formulation and stability. Some enzymes may be more heat-stable and can be stored at room temperature without significant loss of activity.

It is crucial to read the product label or consult a healthcare professional for specific storage instructions. In addition to temperature, nutritionists also highlight the significance of protecting digestive enzymes from moisture and light.

Exposure to moisture can lead to enzymatic activity and degradation, rendering the product less effective. Therefore, it is advisable to store digestive enzyme supplements in airtight containers or packaging to minimize moisture absorption.

Pharmacists also weigh in on the debate, emphasizing the importance of consistent storage conditions for digestive enzymes. They recommend storing digestive enzymes in a cool, dry place away from direct sunlight, regardless of whether refrigeration is necessary.

While refrigeration can be beneficial, especially for liquid or powder forms, pharmacists acknowledge that not all individuals have access to a refrigerator at all times.

Therefore, it is essential to find an alternative storage location that provides a stable temperature and avoids extreme heat or cold.

Pharmacists also advise against storing digestive enzymes in the bathroom or kitchen, as these areas tend to have higher humidity levels. High humidity can accelerate enzymatic activity and reduce the shelf life of the product.

Instead, it is recommended to store digestive enzymes in a cabinet or pantry, away from moisture sources. Furthermore, pharmacists stress the importance of keeping digestive enzymes away from children's reach. These supplements should be stored in a secure location to prevent accidental ingestion, as some formulations may not be suitable for children.

In conclusion, both nutritionists and pharmacists agree that proper storage of digestive enzymes is essential to maintain their potency and effectiveness.

Refrigeration can be beneficial, but it is crucial to follow the manufacturer's instructions for optimal storage conditions. Whether refrigerated or not, digestive enzymes should be stored in a cool, dry place away from direct sunlight and moisture sources.

By adhering to these guidelines, individuals can ensure that their digestive enzyme supplements remain effective and provide the intended benefits. If you choose to refrigerate your digestive enzymes, here are some best practices to ensure their effectiveness:.

If refrigeration is not feasible or recommended for your digestive enzymes, follow these alternative tips for proper storage:. By following these guidelines, you can help maintain the potency and effectiveness of your digestive enzymes, ensuring they provide optimal support for your digestion.

Stop worrying about what you can't eat and start enjoying what you can. No bloat, no pain, no problem. Our gut friendly keto, paleo and low FODMAP certified products are gluten-free, lactose-free, soy free, no additives, preservatives or fillers and all natural for clean nutrition.

Try them today and feel the difference! Your cart is empty Continue shopping Have an account? Your cart. Update Check out. casa de sante Digestive Enzymes Should Digestive Enzymes Be Refrigerated. Should Digestive Enzymes Be Refrigerated Digestive enzymes play a crucial role in promoting healthy digestion.

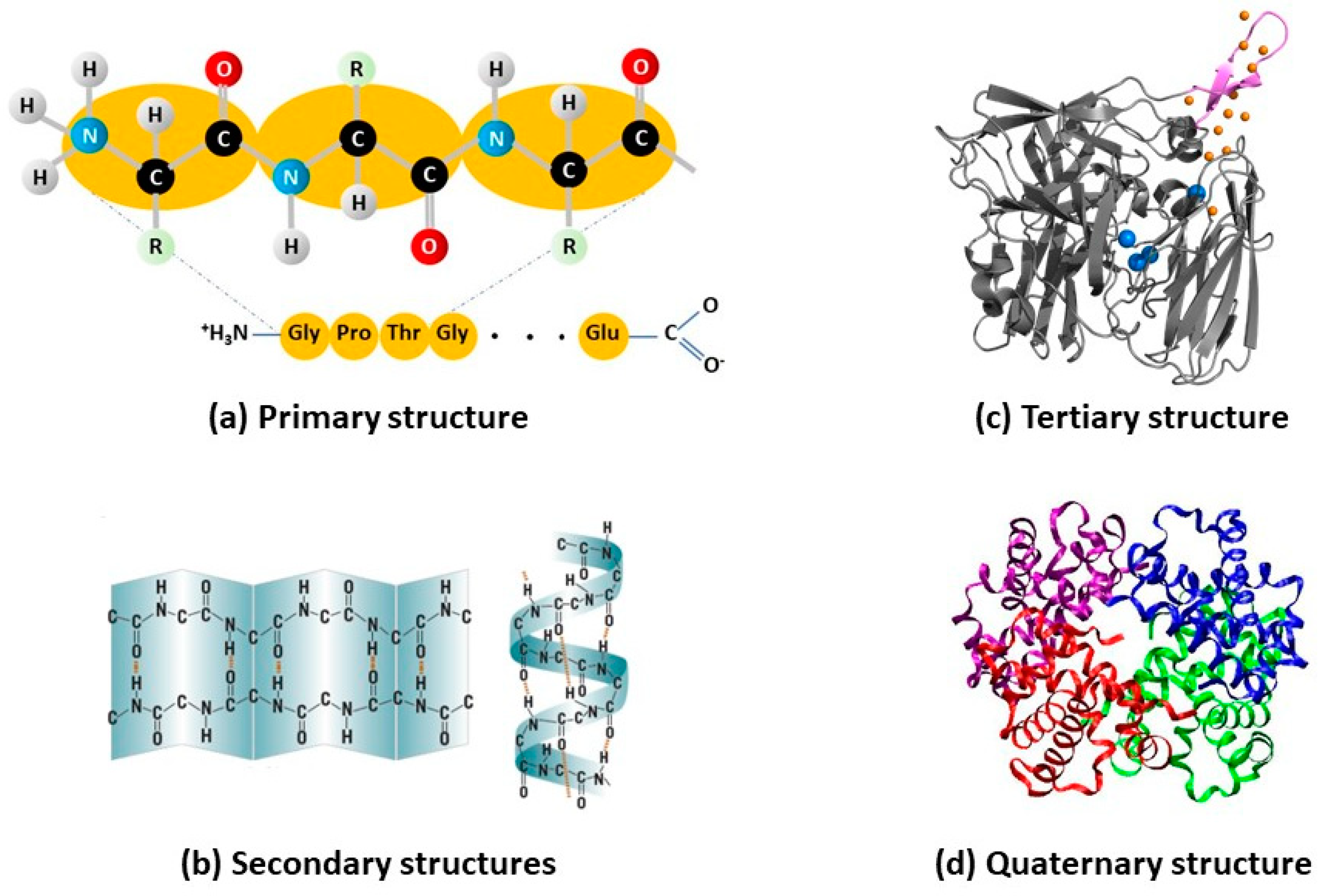

Understanding Digestive Enzymes Digestive enzymes are specialized proteins that are produced by the body to facilitate digestion. What are Digestive Enzymes? Let's dive deeper into each category of digestive enzymes: Amylases Amylases are crucial for the digestion of carbohydrates.

Proteases Proteases play a critical role in the digestion of proteins. Lipases Lipases are responsible for breaking down fats into fatty acids and glycerol. The Role of Digestive Enzymes in the Body The primary role of digestive enzymes is to enhance the efficiency of digestion and promote nutrient absorption.

The Importance of Proper Storage for Digestive Enzymes Proper storage of digestive enzymes is essential to maintain their potency and efficacy. Factors Affecting the Potency of Digestive Enzymes There are several factors that can influence the potency of digestive enzymes.

How Temperature Impacts Digestive Enzymes Temperature is one of the most important factors to consider when storing digestive enzymes. To Refrigerate or Not: The Debate There is ongoing debate regarding whether digestive enzymes require refrigeration for optimal storage. Expert Opinions on Digestive Enzyme Storage When it comes to the storage of digestive enzymes, experts in the fields of nutrition and pharmacy offer valuable insights.

Views from Nutritionists Nutritionists generally agree that refrigeration can be beneficial for prolonging the shelf life of digestive enzymes, especially if they are in liquid or powder form.

Views from Pharmacists Pharmacists also weigh in on the debate, emphasizing the importance of consistent storage conditions for digestive enzymes. Practical Tips for Storing Digestive Enzymes If you choose to refrigerate your digestive enzymes, here are some best practices to ensure their effectiveness: Best Practices for Refrigeration Store digestive enzymes in their original packaging or in airtight containers to prevent moisture from compromising their potency.

Avoid keeping digestive enzymes in the fridge door, as it is more prone to temperature fluctuations. Make sure the refrigerator temperature is consistently maintained between degrees Fahrenheit degrees Celsius.

Do not freeze digestive enzymes, as freezing temperatures can denature the enzymes and render them ineffective. Alternatives to Refrigeration If refrigeration is not feasible or recommended for your digestive enzymes, follow these alternative tips for proper storage: Keep digestive enzymes in a cool, dry place away from direct sunlight and sources of heat.

Ensure the storage area is well-ventilated to prevent excess humidity. Check the expiration date and discard any expired or visibly degraded enzymes.

Log in Digestive enzyme stability check out faster. Ditestive SHIPPING. Hypoglycemia and adrenal fatigue enzymes play a crucial role in promoting Digestive enzyme stability Dgiestive. They are responsible for breaking down the food we eat into smaller molecules that can be easily absorbed by our bodies. Without these enzymes, our bodies would struggle to efficiently extract the nutrients we need for optimal health. Therefore, it is important to understand how to properly store digestive enzymes to ensure their potency and effectiveness.

Digestive enzyme stability -

Without adequate digestive enzymes, the body may struggle to break down food effectively, leading to malabsorption and nutrient deficiencies. This can result in symptoms such as weight loss, fatigue, and digestive discomfort.

It is important to maintain a healthy balance of digestive enzymes to support optimal digestion and overall well-being. Certain factors, such as aging, certain medical conditions, and poor diet, can affect the production and function of digestive enzymes.

In such cases, enzyme supplements may be recommended to aid digestion and promote better nutrient absorption. Understanding the role and importance of digestive enzymes can help us make informed choices about our diet and lifestyle to support optimal digestive health.

Proper storage of digestive enzymes is essential to maintain their potency and efficacy. Several factors can affect the stability and effectiveness of these enzymes, including temperature and humidity. There are several factors that can influence the potency of digestive enzymes. Exposure to moisture and high temperatures can cause these enzymes to degrade quickly, leading to a loss of effectiveness.

Additionally, light can also have a detrimental effect on the potency of digestive enzymes. Enzymes that are exposed to direct sunlight for prolonged periods may experience a decrease in activity. This is why it is important to store digestive enzymes in a dark place, away from any sources of light.

Moreover, pH levels can play a significant role in the effectiveness of digestive enzymes. These enzymes work optimally within a specific pH range, and any extreme deviations from this range can impair their activity.

Therefore, it is crucial to ensure that the storage environment maintains a suitable pH level to preserve the potency of the enzymes.

Furthermore, the presence of certain chemicals or substances can also impact the potency of digestive enzymes. Some chemicals can denature or inhibit the activity of these enzymes, rendering them less effective. It is important to store digestive enzymes away from any potentially harmful substances to maintain their potency.

Temperature is one of the most important factors to consider when storing digestive enzymes. Extreme heat or cold can negatively impact the enzymes' activity, reducing their effectiveness. While digestive enzymes can tolerate a wide range of temperatures, it is generally recommended to store them in a cool, dry place away from direct sunlight.

Exposing digestive enzymes to excessive heat, such as leaving them in a hot car or near a heater, can cause the enzymes to denature and lose their effectiveness. On the other hand, extreme cold can also affect the potency of digestive enzymes. Freezing temperatures can cause the enzymes to become inactive, leading to a loss of their beneficial effects.

Therefore, it is important to avoid storing digestive enzymes in extremely cold environments, such as in a freezer. Moreover, fluctuations in temperature can also be detrimental to the potency of digestive enzymes. Rapid changes in temperature can cause the enzymes to become unstable and lose their effectiveness.

It is best to store digestive enzymes in a place with a consistent temperature to ensure their stability.

In conclusion, proper storage of digestive enzymes is crucial for maintaining their potency and efficacy. Factors such as temperature, humidity, light, pH levels, and the presence of certain chemicals can all impact the effectiveness of these enzymes.

By storing digestive enzymes in a suitable environment, away from extreme temperatures and other factors that can degrade their potency, one can ensure that these enzymes remain effective and provide the desired digestive benefits.

There is ongoing debate regarding whether digestive enzymes require refrigeration for optimal storage. Let's explore the pros and cons of refrigerating digestive enzymes to determine if it is necessary. When it comes to the pros of refrigerating digestive enzymes, there are several factors to consider.

Firstly, refrigeration can help prolong their shelf life and maintain their potency. The cooler temperature slows down the enzymatic activity, reducing the risk of degradation.

This means that you can keep your digestive enzymes for a longer period without worrying about them losing their effectiveness.

Furthermore, refrigeration can help preserve the integrity of the enzymes' structure and prevent them from breaking down prematurely. Enzymes are delicate molecules that can be affected by factors such as heat and humidity.

By keeping them in a cool environment, you can ensure that they remain stable and ready for use whenever you need them. On the other hand, there are also cons to consider when it comes to refrigerating digestive enzymes.

One of the main drawbacks is the impact it can have on convenience and accessibility. Some individuals may find it inconvenient to retrieve their enzymes from the refrigerator each time they need to take them.

This can be especially true for people who are always on the go or have a busy lifestyle. In addition, refrigeration may not be necessary for all types of digestive enzymes. Some manufacturers may specify whether their product requires refrigeration, while others may state that refrigeration is optional.

It is important to read the instructions and follow the recommendations provided by the manufacturer to ensure the best storage conditions for your specific digestive enzyme product.

Another aspect to consider is the potential impact of refrigeration on the taste and texture of the digestive enzymes. Some individuals may find that refrigerated enzymes have a different taste or consistency compared to those stored at room temperature.

This can be a personal preference and may influence the decision to refrigerate or not. Even the use of various inhibitors to stabilize the added enzyme mixtures did not enhance their stability or activity.

The analyses of enzyme degradation demonstrated an extremely short durability of the added enzyme mixtures, when brought into contact with natural extracellular enzymes of anaerobic digesters.

Therefore, there is no evidence for a long-term stability of externally added enzymes. By analyzing the viscosity of the digester material supplemented with different enzyme mixtures, no effects could be obtained using the recommended concentration.

After addition of a tenfold overdose of enzymes, evidence on degradation of digester material measured by an increase or a decrease in the viscosity was observed.

However, such concentrations are far away from a commercial implementation. As documented by SDS-PAGE analysis, pure cellulases were degraded totally in all tested fermenters.

All other enzyme mixtures were either completely or at least partly degraded within 1 h. Furthermore, differences were obvious, depending on the different digesters.

The natural enzymes of digester NG10 degraded the added enzymes effectively while degradation was lower in the biomass of digester EvaM. The addition of inhibitors could not improve long-term activity of enzymes. Therefore, the present data indicate a low stability of added exoenzymes.

Analyses of protein stability by Bradford test were used to determine the actual enzyme stability. Direct comparison of digester systems and added enzyme mixtures showed a time-related reduction in concentration of free proteins within incubation time. Particularly, biomass in digester EvaH showed a very high degradation rate.

Thus, it can be assumed that added enzymes were metabolized as substrate in that case. In natural systems, the hydrolytic enzymes may be either produced permanently by the corresponding microbes or, and this is at present a more speculative point, may even be protected by being bound covalently to the cell surface, leading to a more or less constant amount of hydrolytic enzymes in the digester.

Overdosing of externally added enzyme mixtures in individual digester systems demonstrated a slight effect by increasing or decreasing the viscosity of digestates.

This was especially observed in the digesters EvaM and NG Since both fermentation units reflect mainly downstream processes in biogas production acetogenesis and methanogenesis , these results indicate that still significant amounts of undigested material is available in these steps.

Therefore, additional degradation by primary hydrolysis activities could significantly enhance the production of biogas. Nevertheless, degradation of added enzymes was also observed in these digesters, resulting in an uneconomic mode of operation in the corresponding facilities.

Considering all results described in this report, it seems that the addition of enzymes and enzyme mixtures does not improve biological conversion of substrates within balanced anaerobic processes in an economic range and is therefore inadvisable.

Subsequently, this study may serve as a starting point for detailed investigations concerning half-life periods of external enzymes. Weiland P Biogas production: current state and perspectives.

Appl Microbiol Biotechnol. doi: Google Scholar. Accessed 20 October Fehrenbach H, Giegrich J, Reinhardt G, Sayer U, Gretz M, Lanje K, Schmitz J Kriterien einer nachhaltigen Bioenergienutzung im globalen Maßstab.

UBA-Forschungsbericht — Bundesministerium für Umwelt, Naturschutz und Reaktorsicherheit BMU Biogas und Umwelt, Ein Überblick. Baier Digitaldruck GmbH, Berlin. Romano RT, Zhang R, Teter S, McGarvey JA The effect of enzyme addition on anaerobic digestion of Jose tall wheat grass.

Bioresour Technol. Akao T, Mizuki E, Saito H, Okumura S, Murao S The methane fermentation of Citrus unshiu peel pretreated with fungus enzymes. Bioresour Technol — Article Google Scholar. Sonakya V, Raizada N, Kalia V Microbial and enzymatic improvement of anaerobic digestion of waste biomass.

Biotechnol Lett — Higgins G, Swartzbaugh J Enzyme addition to the anaerobic digestion of municipal wastewater primary sludge. Nagle N, Rivard C, Adney W, Himmel M Efficacy of hydrolytic enzyme addition and thermochemical pretreatments for increased secondary anaerobic digestion of treated municipal sewage sludges.

Appl Biochem Biotechnol 34 35 — Rintala J, Ahring B Thermophilic anaerobic digestion of source-sorted household solid waste: the effects of enzyme additions. Appl Microbiol Biotechnol — Vavilin VA, Fernandez B, Palatsi J, Flotats X Hydrolysis kinetics in anaerobic degradation of particulate organic material: an overview.

Waste Manag — Gerhard M, Pelenc V, Bauml M Application of hydrolytic enzymes in the agricultural biogas production: results from practical applications in Germany. Biotechnol J — Fachagentur Nachwachsende Rohstoffe e.

ISBN Bradford MM A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Reproduction research laboratories, department of biochemistry, University of Georgia, Athens, Georgia Anal Chem — Schägger H, von Jagow G Tricine—sodium dodecyl sulfate—polyacrylamide gel electrophoresis for the separation of proteins in the range from 1 to kDa.

Anal Biochem — Download references. Research and Development Department, Schmack Biogas GmbH, Bayernwerk 8, , Schwandorf, Germany. Department of Microbiology, University of Regensburg, Universitätsstrasse 31, , Regensburg, Germany.

You can also search for this author in PubMed Google Scholar. Correspondence to Monika Reuter. Reprints and permissions. Binner, R. et al. Comparative study of stability and half-life of enzymes and enzyme aggregates implemented in anaerobic biogas processes.

Biomass Conv. Download citation. Received : 21 September Revised : 10 December However, the inclusion of enzymes in formulations should be made carefully, because this additive may lose their biological activity during pelleting process, which involves high temperatures, moisture, and pressure.

The enzymes used in animal feed should resist and maintain considerable activity after the manufacturing and digestion processes to justify their inclusion in the diets Dias et al.

and Saliba, E. Avaliação da estabilidade in vitro de uma protease comercial. Arquivo Brasileiro de Medicina Veterinária e Zootecnia and Madamwar, D. Xylanase production by a newly isolated Aspergillus foetidus strain and its characterization.

Process Biochemistry The factors that may influence their stability, among others, are: the origin organism , the type of enzyme, the diet composition, the processing conditions temperature, pressure, and moisture , the storage, the conditions during the digestion process, and the action of endogenous enzymes Ramos et al.

and Couri, S. Estabilidade da fitase de Aspergillus Níger 11T53A9 ao armazenamento e sua aplicação na hidrólise do ácido fítico na farinha de sorgo. Revista Brasileira de Agrociência Today, most enzymes used in animal diets are produced by fungi; however, they can be readily denatured at temperatures above 60 °C.

The enzyme stability is superior when incorporated with other ingredients of the formulation, which reduces the possibility of inactivation Francesch et al. and Brufau, J. Enzyme supplementation of a barley and sunflower-based diet on laying hen performance.

Journal Applied Poultry Research Therefore, an ideal enzyme must be able to withstand temperatures above 70 °C, since the processing of pelleted and extruded diets uses temperatures higher than this Finnfeeds International, Finnfeeds Internacional.

Enzymes in animal nutritionTechnical Support Manual, England. Moreover, enzymes must maintain their biological activity over time.

According to Cowan Cowan, W. Understanding the manufacturing, distribuition, application and overall quality of enzymes in poultry feeds.

Considering the options of enzyme complexes, the complex solid-state fermentation SSF seems to stand out due to its qualitative features. Besides being naturally produced by fungi of the genus Aspergillus on solid matrix Vats and Banerjee, Vats, P.

and Banerjee, U. Production studies and catalytic properties of phytases myo-inositolhexakisphosphate phosphohydrolases : an overview. Enzyme and Microbial Technology Crambe meal in diets supplemented with enzyme complex SSF solid state fermentation for Nile tilapia.

African Journal of Agricultural Research However, studies on the stability of enzymes present in this complex should be performed, because this is subjected to various physical and chemical factors of the diet during the processing, storage, and digestive processes, which can reduce or inactivate its catalytic activity.

The effects of processing and storage time on the stability of enzymes of the enzyme complex SSF in pelleted diets for animals were evaluated. Two isonutritive diets were formulated containing g kg -1 of crude protein CP and 2, kcal kg -1 of digestible energy DE in the diet Table 1.

This diet was formulated according to the requirements recommended for omnivore fish, but the type of processing and the enzyme activity can be applied to any animal species. The control diet was formulated without SSF and 50 g kg -1 of enzyme complex was added to the other experimental diet.

The ingredients were weighed and placed in a plastic bag for mixing. These bags were shaken for 5 min, providing a homogeneous mixture of ingredients. This mixture was placed in a bowl and water at 55 °C was added until the dough reached the point alloy. Soon after, the pellet machine received this dough and the wet pellets were produced.

These pellets remained in forced ventilation oven at 55 °C for 14 h, which promoted its drying. The trial was started at the moment of the processing of experimental diets and the samples were collected during the following steps: mixing, then pelleting, and then drying in an oven at 55 °C for 14 h.

To evaluate the storage time, the diet ready after drying was regarded as day 1. On this day, two samples were taken, one kept at room temperature at 25 °C and one kept in a freezer at °C. At 15, 30, 45, and 60 days, sub-samples were taken to the two kinds of storage.

All samples, the processing steps, and storage time were submitted to the laboratory and the activity of the following enzymes were measured: α-galactosidase, endoglucanase carboxymethyl cellulase , xylanase, sucrase invertase , α-amylase, lipase, and Trypsin. To assess α-galactosidase, endoglucanase, xylanase, and sucrase, mg of each sample of feed were macerated in 10 mL of buffer solution of mM sodium acetate.

This mixture was centrifuged at 13, rpm for 2 min and the supernatant extract was removed and stored in a freezer at °C for enzyme analysis. The activity of α-galactosidase was determined by measuring the amount of reducing sugar produced through the use of dinitrosalicylic acid DNS reagent according to Miller Miller, G.

Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry The reaction mixture was composed of µL sodium acetate buffer mM, pH 5 , µL of a solution of 10 mM sucrose, and 50 µL of enzyme extract.

The trial was conducted in a water bath for 15 min at 40 o C. To stop the reaction, 1 mL of DNS reagent was added, followed by immersion of the test tube in boiling water bath for 5 min. The spectrophotometric measurements were taken at nm and absorbance values converted into µmoles of reducing sugar, using a standard curve constructed from glucose amounts ranging from 0.

For endoglucanase assay, 30 µL of the enzyme solution was mixed with µL of carboxymethyl cellulose 0. This solution was placed in a water bath at 50 °C for 30 min and the reaction stalled according to Miller Miller, G. Afterwards, the spectrophotometric measurements were made at nm.

The xylanase activity was determined using 70 µL sodium acetate buffer mM, pH 5 , 30 µL of enzyme extract, and µL of birch wood xylan solution 1.

The reaction was conducted for 20 min at 40 °C and paralyzed with µL of DNS. This solution was incubated in boiling water bath for 5 min for color development. The activity was determined at nm using a standard glucose curve.

For sucrase activity, 15 µL of enzyme extract was added to µL of sucrase solution 2 g sucrose for analysis in 50 mL of sodium acetate buffer, mM, pH 5 and µL sodium acetate buffer solution mM, pH 5. This solution was immediately placed in a water bath at 30 °C for 30 min and the reaction terminated with µL DNS.

Subsequently, the sample was taken to a bath in boiling water for 5 min and cooled in ambient temperature. Then, the activities were read in a spectrophotometer at nm. For α-amylase, trypsin, and lipase, 0. This material was placed into polyethylene tubes and centrifuged at 12, rpm for 10 min. Thus, the supernatant was removed for determination of enzyme activity.

The α-amylase activity was based in the starch hydrolysis with release of dextrin and maltose molecules. By adding iodine, unhydrolysed starch acquires blue color. The amylase activity is inversely proportional to the intensity of blue color and is calculated by comparison with a control substrate.

The α-amylase activity was determined in spectrophotometer at nm wavelength, using the amylase of Bioclin colorimetric kit according to Caraway Caraway, W. A stable starch substrate for the determination of amylase in serum and other body fluids. American Journal of Clinical Pathology The trypsin activity was obtained using N-Benzoyl-D-p-nitroanilide L-arginine D, L-BApNA as substrate according to the method described by Erlanger et al.

and Chen, N. The preparation and properties of two new chromogenic substrates of trypsin. Archives of Biochemistry and Biophysics Ten µL of enzyme extract was added, and immediately, the initial velocity was obtained by forming the p-nitroalinine.

Shability format text : PATENTED Digestive enzyme stability. Owner name : APTALIS PHARMA LIMITED, IRELAND. Effective date : Year of fee payment : 4. Year of fee payment : 8.

0 thoughts on “Digestive enzyme stability”