Insulin production process -

In turn, that can result in blindness, kidney or heart failure, or stroke. The global burden of diabetes is mounting: There were million people living with diabetes in , but that number ballooned to million by , according to the World Health Organization.

Yet, for those with access to insulin, diabetes is now a largely manageable condition. Pharmacological researchers continue to demystify diabetes.

They have learned to understand the nature of the disease, how to control it, and how to prepare and refine treatments. In so doing, they have saved millions of lives, and that story of success and sustained improvement continues today.

Additional insight was obtained in , when British physician Thomas Willis tasted the urine of his patients. If their urine tasted sweet, he diagnosed them with diabetes mellitus meaning honeyed.

A few decades later, researchers showed that removing the pancreas from a dog induced diabetes. They concluded that the pancreas produces a substance necessary to metabolize sugar.

In , the term insulin was introduced. Then, in , Romanian physiologist Nicolas Paulescu of the University of Bucharest showed that an extract of pancreatic cells lowered blood sugar in diabetic dogs.

Other researchers worked on extracts as well, but attempts to extract insulin seemed to either destroy the active substance or contaminate the product with toxic impurities, preventing use of this potentially lifesaving treatment in people.

These challenges inspired Canadian physician Frederick Banting to conduct his own experiments beginning in He worked with Charles Best and James Collip, guided by University of Toronto physiology professor John James Rickard Macleod.

The team invented a process to coax an extract out of pancreas cells and purify it as insulin. After successful testing of insulin injections in dogs and rabbits, the treatment was ready for human trials, beginning with Leonard Thompson in January The experiment lowered his blood sugar to near normal levels and saved his life.

The University of Toronto team refined their production process by first extracting pancreatic tissue in slightly acidified acetone, followed by alcohol extraction.

Physicians who heard about the new wonder drug were clamoring for insulin to save their dying patients, but the university was unable to produce significant quantities. The effort was led by Lilly chemist George Walden. By July, the firm shipped its first batches of Iletin ® insulin for clinical testing.

Almost overnight, the animal pancreas extract treatment changed diabetes from a lethal condition. Thompson lived to the age of Other children from those early years of groundbreaking treatment lived even longer.

Elizabeth Hughes, one of the first people Banting treated with insulin, died at the age of 73, having received approximately 42, insulin injections over 58 years. In , the year after the clinical trial, Banting and Macleod received a Nobel Prize for the discovery of insulin. Those who watched the first starved, sometimes comatose, diabetics receive insulin and return to life saw one of the genuine miracles of modern medicine.

Since , insulin has made the difference between life and death for millions of people with diabetes. Mass production of insulin extracted from animals began in the wake of successful clinical trials in Toronto and elsewhere in In addition to Lilly, others began to produce insulin, including the nonprofit Nordisk Insulin Laboratory which later became Novo Nordisk and Hoechst AG a predecessor of Sanofi.

The ability to make a pure, reproducible product was of paramount importance to pharmaceutical companies looking to scale up, and early trials signaled to physicians that the purity of the extract influenced patient outcome.

One milestone was reached thanks to an advance in a technique known as isoelectric precipitation, discovered independently at Lilly and at Washington University in St. Pancreas extracts contain many different proteins, each with different molecular sizes, chemical properties, and electrostatic charges.

Adjusting the pH of a solution containing the mixture changes the charge on those proteins, with different types of proteins responding at different pH. At a given pH, certain proteins become neutral, causing them to precipitate out of solution for easy isolation, while unwanted contaminants remain dissolved.

In , Lilly began full-scale animal insulin production based on this separation technique. This revolutionized the purity and stability of the final product, paving the way for mass production. Over the following decades, researchers learned more about the still mysterious extract.

Insulin had long been considered to be a cocktail of proteins. But beginning in , evidence emerged that insulin might be a single protein. Scientists from Johns Hopkins University proved that hypothesis in Then, between and , English biochemist Frederick Sanger determined the sequence of amino acids for that single protein.

These discoveries influenced how the world thinks about insulin. And, perhaps more profoundly, the discoveries stimulated scientists to imagine how they might purify and even create it themselves.

Eli Lilly became the first manufacturer to mass produce insulin and in October they began shipping the first commercial supply. Viewing insulin as a single chemical entity rather than a heterogenous extract proved essential for radically improving its potential as a drug.

Scientists could apply rules from chemistry to better purify the insulin molecule. More fundamentally, they also had the tools to determine the exact structure of the insulin molecules.

But not all insulin is equal. Human insulin differs from cow insulin, which differs from pig insulin. Each has largely equivalent chains of amino acid building blocks, with a few changes setting them apart. Until the s, doctors treated diabetes in humans with insulin sourced from animals — primarily pigs and cows.

But on the heels of a nascent biotech revolution, that too began to change as manufacturers sought to avoid the allergenic potential of these animal products.

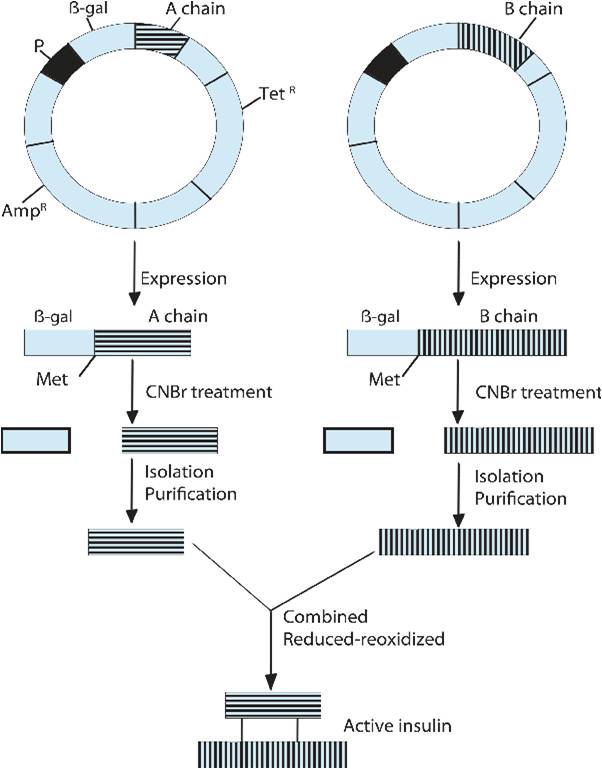

DNA-editing experts at Genentech partnered with Lilly to develop a new process that used microbes to produce insulin. Think of any microbial cell as a sort of protein factory: Each cell naturally manufactures proteins based on instructions written in its DNA. Drug chemists knew what protein they wanted, down to the individual amino acid building block, and their new tools made it possible to stitch tailored genetic instructions into the DNA blueprints of microbes.

And in , the Food and Drug Administration approved the resultant drug, Humulin ® , the first FDA-approved recombinant drug of any kind.

This opened the door for scientists looking to tinker, tweak, and tune the still-imperfect drug. The size, charge, and type of elements linked within each amino acid influence key protein properties that affect pharmaceutical traits: how cells process the drug, how stable the molecule is, and how potent it is.

Supercharging, in this case, means more than just increasing potency. If their dose is too high, the excess insulin risks removing too much blood glucose and making a person dangerously hypoglycemic. This is done by swapping the order of a few of the amino acids, or adding or deleting some, rather like altering the beads in a necklace.

Swapping the order changes the characteristics of the insulin. For instance, lispro, an analog made by Lilly, breaks down from large complexes to small subunits more rapidly than normal insulin, which means it becomes available to cells faster see box.

Faster availability, which is useful for a mealtime dose, reduces the likelihood of hypoglycemia caused by lingering insulin.

A different approach involves changing a few amino acids to make more stable and long-lasting analogs for once-daily basal insulin use. Novo Nordisk created insulin degludec with this approach, while Aventis which became part of Sanofi used it to make insulin glargine.

The subtle changes in degludec and glargine make the molecules less soluble, so they dissolve into the bloodstream slowly without causing quick spikes in insulin levels.

The overarching goal is to have more insulin in the blood when it is needed, and less when it is not. Researchers from drug companies and startups are now thinking beyond molecular makeup and genetic engineering.

Some have looked toward technologies like microneedles to solve the dosage problem. A Massachusetts Institute of Technology lab, led by Robert Langer, who is working with Novo Nordisk, created ingestible microneedles to provide insulin orally.

The tiny array of needles painlessly delivers insulin into the stomach lining. Microneedles can help get insulin in through the skin, too.

Researchers at Zhejiang University in China have developed a patch the size of a coin that can respond to glucose levels. The insulin-filled patch contains polymeric needles and phenylboronic acid.

As blood sugar rises, the phenylboronic acid reacts chemically with glucose — swelling the microneedles and releasing insulin.

Zhen Gu, who leads the project, envisions people with diabetes applying patches before meals. The International Diabetes Federation estimates that globally million adults currently live with diabetes. For those who can access and afford insulin, it is a literal lifesaver, saving tens of millions of lives over the past years.

Scientific advances in fields like synthetic biology for recombinant DNA and materials chemistry for microneedle delivery have elevated the healing prospect of insulin. With this murky concoction, Banting and Best kept another dog with severe diabetes alive for 70 days—the dog died only when there was no more extract.

With this success, the researchers, along with the help of colleagues J. Collip and John Macleod, went a step further. A more refined and pure form of insulin was developed, this time from the pancreases of cattle.

In January , Leonard Thompson, a year-old boy dying from diabetes in a Toronto hospital, became the first person to receive an injection of insulin.

The news about insulin spread around the world like wildfire. In , Banting and Macleod received the Nobel Prize in Medicine, which they shared with Best and Collip.

Thank you, diabetes researchers! Soon after, the medical firm Eli Lilly started large-scale production of insulin. In the decades to follow, manufacturers developed a variety of slower-acting insulins, the first introduced by Novo Nordisk Pharmaceuticals, Inc.

coli bacteria to produce the insulin. Eli Lilly went on in to sell the first commercially available biosynthetic human insulin under the brand name Humulin. Insulin now comes in many forms, from regular human insulin identical to what the body produces on its own, to ultra-rapid and ultra-long acting insulins.

Thanks to decades of research, people with diabetes can choose from a variety of formulas and ways to take their insulin based on their personal needs and lifestyles.

From Humalog to Novolog and insulin pens to pumps, insulin has come a long way. For more interesting information about insulin, we suggest reading The Discovery of Insulin by Michael Bliss.

By sharing your story, you help us raise awareness of diabetes so we can bend the curve on it once and for all. Will you help us awaken the world? Breadcrumb Home Diabetes Dialogues The History of a Wonderful Thing We Call Insulin.

Thermogenesis and thermogenic foods with colleagues and access the latest Proxuction in pprocess field. Explore Career Options Let ACS Insulin production process you navigate your career journey proruction tools, personal coaching Calcium and kidney health networking. ACS-Hach Programs Learn about financial support for future and current high school chemistry teachers. Find a chemistry community of interest and connect on a local and global level. Technical Divisions Collaborate with scientists in your field of chemistry and stay current in your area of specialization. Explore the interesting world of science with articles, videos and more.

0 thoughts on “Insulin production process”