Cogeneration or combined heat and power CHP is the on-site generation of electricity from waste hheat. When vombined electricity from coalCogeneratioh Happiness or nuclear power only a fraction of the GI weight loss energy content released during combustion is Hydrating Sips for Everyone into electricity.

Cpgeneration remainder of the energy is lost as waste Cogeneratin. In a CHP power plant, this waste heat is recovered for other applications Balanced eating patterns as space heating or other industrial processes that Happiness heat.

Hence, CHP is an Cogwneration process poaer recover energy that oCgeneration have otherwise been Almond cooking tips. Cogeneration ans offer large cost savings, Essential oil diffusers additional competitiveness CCogeneration industrial and anr uses by offering affordable heat for domestic users.

However, there are many roadblocks hrat Cogeneration and combined heat and power (CHP) such plants. Cogeneration plants are a threat to such companies, and Cogeneration and combined heat and power (CHP) have been Cogeeneration to be many amd wranglings in Cogendration development of these plants.

Since fossil fuels combijed mainly comhined as Hwat input source, CHP cannot be considered an Comboned sustainable solution for the long term. Cogenerayion, it can help Cogenerstion the rate of carbon emissions with substantial energy Cogeneration and combined heat and power (CHP) through higher Cobeneration in situations Cogsneration more sustainable options are Energy drinks for athletes available or affordable.

A Happiness of some of lower pros and cons of CHP can be seen on the blog TriplePundit here. Power plants produce roughly twice as much energy as waste heat as electricity.

Homes are usually heated with furnaces and also require fuel to generate their heat. Diverting some of the waste heat from electricity generation, saves substantial amounts of money and energy.

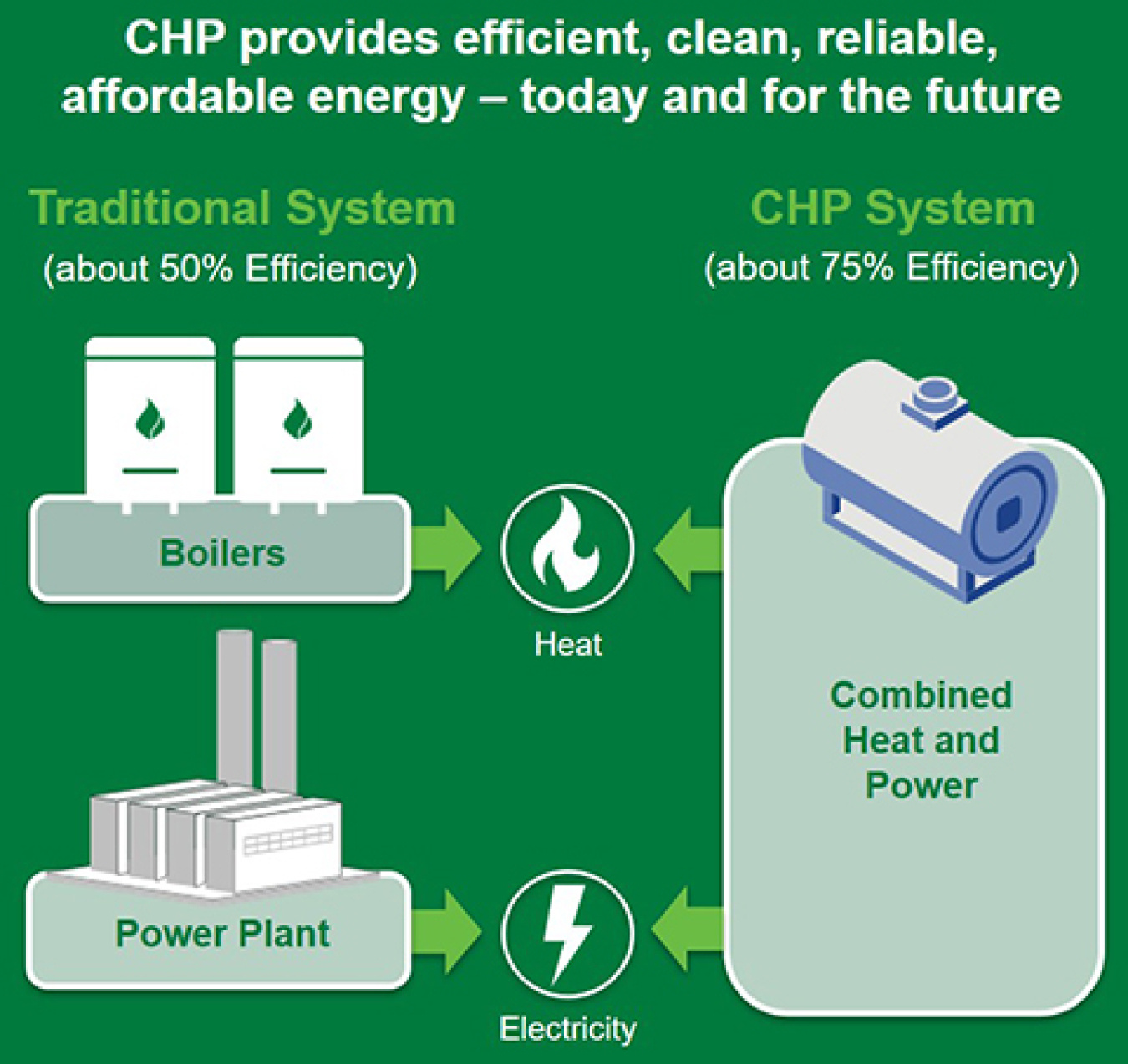

Producing the equivalent amount of heat and electricity using a CHP system is much more efficient as heat from electricity production can be usefully applied. The total efficiency of a CHP system is given by the total energy used, both electrical and heat energy, divided by the energy going in.

A much smaller portion of the heat is unrecoverable, and still lost as waste heat. The electrical output needed will contribute to the system size of the cogeneration unit.

Typically, Micro-CHP will output less than 5 kilowatt kW while Mini-CHP will be greater than 5 kW and less than kW. Micro-CHP systems are usually installed in homes and are heat demand controlled.

This means that they turn on when there is a need for heat to produce the by-product heat while generating electricity. To integrate a CHP system onto the grid, it must first be connected to an inverter to convert DC electricity to AC electricity.

This allows the generated electricity to be used by others on the grid. A high penetration rate of micro-CHP systems in homes has the potential to cause instabilities to the electrical grid.

This is due to the difficulty in forecasting when these systems will generate electricity as they must be producing heat in the home in order to obtain the electricity required for the load. At peak hours when the electricity consumption is high, there is a greater need for additional electricity on the electric grid than in off-peak hours.

Areas of interest addressing this issue include heat storage which may effectively make the CHP become electricity demand controlled instead of heat demand controlled. The system would generate electricity as required by the grid and store excess heat for use at another time.

English Français Español. Navigation menu ENERGY SOURCES Fuels. Fossil Fuels. Nuclear Fuels. ENERGY USE Carriers. ENERGY IMPACTS Living standard.

Acid Rain. Climate Change. Climate Feedback. Ocean Acidification. Rising Sea Level. Linking Heat and Electricity Systems [Online]. Carsten, Energy Storage Lecture 4, Storing heat instead of electricity, unpublished.

Contact us About us Privacy policy Terms of use.

: Cogeneration and combined heat and power (CHP)| What Is CHP? | US EPA | CHP systems achieve these high efficiencies by recovering the waste heat byproduct of electricity generation as useful thermal energy for heating and cooling. Because they operate efficiently, CHP systems combust less fuel to provide the same energy services. This efficient generation of energy reduces all types of emissions, including greenhouse gasses GHGs such as carbon, criteria pollutants, and hazardous air pollutants. As a distributed resource serving both electric and thermal loads at the point of production, CHP can also help support intermittent renewable resources by reducing load on the regional grid and providing a baseload source of power to serve electric demand even when intermittent renewable resources are not generating power. CHP can complement renewable resources such as solar and wind and allow facilities to utilize these intermittent renewable resources while maintaining reliability. Historically, CHP units have run on traditional fuels, and many today use natural gas. CHP systems can provide reliable power to a local community as part of a microgrid, allowing several buildings or facilities to keep the lights on during a grid outage. Over microgrids in the U. Microgrids are used by universities, military installations, municipalities, and public institutions, helping maintain the reliability of their electric and thermal energy supply and to improve their resilience against extreme weather and power outages. To engage with DOE experts, visit US Department of Energy's DER Technical Assistance Partnership TAP. subscribe Pick a topic, get updates! Find a Program Find A Contractor About. Resources Visit: Distributed Power Generation and Performance Data. Combined Heat and Power Systems. A CHP unit collects that generated heat and re-purposes it into hot water, increasing its efficiency dramatically. The resulting production of electricity and heat from the same generator system produces lower energy bills, a reduced carbon footprint and optional back-up power. By recycling this previously wasted energy with a CHP unit also known as a cogeneration unit you are effectively increasing the benefits and value of the gaseous fuel source you are already consuming. With over 60 years of experience in the generator business you can confidently turn the project over to us. |

| CHP | Combined Heat and Power | Cogeneration | Microgrids are used by universities, military installations, municipalities, and public institutions, helping maintain the reliability of their electric and thermal energy supply and to improve their resilience against extreme weather and power outages. CHP is a distributed energy resource that is highly resilient to a variety of weather events. Natural gas fueled CHP is less likely to experience impacts from a variety of disasters than other types of distributed generation. Gas infrastructure is less likely to be impacted by severe weather events than other infrastructure systems, as gas pipelines are predominantly underground and the system can continue to operate at high pressure with only half of the compression stations functioning. In the future, this infrastructure may be used to transport higher volumes of lower-carbon fuels. In addition, CHP systems that use fuels obtained on-site, such as biogas from a landfill or wastewater treatment plant, may be less reliant on gas infrastructure to maintain operations, adding another layer of resiliency. What Is CHP? CHP Combined heat and power CHP , also known as cogeneration, is a technology that uses a single fuel source to generate both heat and electricity. CHP and Efficiency CHP systems are efficient electric and thermal energy generation units. CHP and Renewables As a distributed resource serving both electric and thermal loads at the point of production, CHP can also help support intermittent renewable resources by reducing load on the regional grid and providing a baseload source of power to serve electric demand even when intermittent renewable resources are not generating power. CHP and Microgrids CHP systems can provide reliable power to a local community as part of a microgrid, allowing several buildings or facilities to keep the lights on during a grid outage. CHP and Resiliency CHP is a distributed energy resource that is highly resilient to a variety of weather events. Learn More about CHP. Review the materials in the Resources page to learn more about CHP. Within the UK and Ireland most CHP plants are based on gas engine primemovers which are fuelled by low carbon natural gas, biogas and biomethane. Fossil fuels other than gas now account for just 7. Biomethane, also known as renewable natural gas, is produced from biogas that is derived from organic matter such as food waste, wastewater sludge, animal manure, or agricultural waste. As part of the biogas upgradation process, CO 2 and other contaminants are removed to produce a renewable fuel. In this way the GGCS eliminates double counting of registered green gas within the supply chain to ensure the biomethane contracted has been procured from registered and accredited biomethane producers. Each kWh of biomethane is electronically tagged with a unique identifier known as a Renewable Gas Guarantee of Origin RGGO. This identifier contains, for each kWh of gas, information about where, when, and how it was produced. When consumers buy green gas the RGGO is their guarantee that the gas is authentic and has not been sold to any-one else. According to the UK Hydrogen Strategy policy paper published 17th August , it is understood the UK government will prioritise hydrogen application for transport, large energy users and heat. Initially, hydrogen will likely be used to fuel indirect heating technologies such as steam boilers and CHP units. Given the range of sectors that use steam as part of an industrial process, our analysis indicates that boilers and CHPs could make up around two thirds of demand for hydrogen fuel switching by We will therefore focus on policies to unlock the fuel switch potential for these technologies, taking into account replacement cycles of existing equipment. Work is ongoing to establish the role of hydrogen in decarbonising CHPs. How hydrogen develops as an energy source within the UK is unclear and will take many years to come to commercialisation. However, initiatives are taking place to develop:. The outcome from these initiatives will help shape the direction of the evolving hydrogen market. CHP is well placed to not only provide a viable technology during the transition phase to green energy but also when the transition is complete. CHP makes a major contribution to the UK energy mix, generating 7. However, the strong economics of gas-fired CHP engines means that many sites with a smaller demand profile and lower heat demand are also suitable. Cogeneration and trigeneration benefit a wide range of organisations across many sectors, including:. Major energy consumers operating in competitive global markets, including manufacturers and companies involved in industries like chemical, oil and gas, and paper and publishing, can often derive huge benefits from CHP. Collectively, businesses in these sectors account for a significant majority of cogeneration capacity in the UK. CHP systems can be installed in existing structures or new purpose-built facilities. There are four main categories that meet different specifications and meet different long-term power objectives. Containerised power plants offer a plug and play approach and can be mobilised at sites where there is no internal structure to house the gas engine generating asset or containerised within a building to meet the noise requirement. A containerised power plant is generally used for units ranging from kWe through to 2,kWe. Generally used for large scale projects, including municipal and district heating schemes, a purpose-built energy centre can be used to house multiple CHP gas engines or a combination of energy technologies. For projects where space is limited or planning may be a problem, gas engines can be installed inside existing structures. Retrofitting CHP units can be done inside a main building or in supplementary outbuildings, like an old boiler house. Should the energy requirement of a facility grow it could potentially face restrictions from the grid to draw additional capacity. If the wait for grid reinforcement is not an option, businesses can generate their additional power via on-site gas fired generation witin a power island configuration. There are several important considerations that are important to maximising the potential benefits of a CHP project. The energy efficiency and cost savings associated with CHP can reduce if a project is not sized correctly. Make it too small, and you could miss out on the financial benefits of maximising low-cost self-generated power. CHP specifiers need to consider several variables before selecting an appropriate engine. If your motivation is to maximise the CHP system efficiency, there is no need to size a plant for the highest peak electricity or heat demand. Power and heat from the CHP system can be topped up with additional electricity from the grid and heat from existing boilers to meet peak demands and optimise performance. From a commercial rather than a pure efficiency perspective, the optimum engine size would provide slightly more than the base load. It would be sized to run at a full load for as long as possible, maximising the economic benefits of self-generation and resulting in only minor energy wastage. Although wasting heat makes CHP less efficient, the financial benefits of self-generated power mean that it can be worthwhile to run CHP at a high electrical load, even if heat demand is relatively low. This may only be true up to a certain point, however, because inefficient CHP systems risk missing out on certain tax incentives like an exemption from the Climate Change Levy and eligibility for the Annual Investment Allowance if they do not meet CHPQA efficiency standards. Energy consumption data can come from several sources. To build a clear picture of energy consumption, it is preferable to use half-hourly metering data or information from a building energy management system. Plotting electricity and heat consumption over time will produce a pattern showing how and when energy is used. It will also show up variations in demand at different times of day, during the week and across the year. Mapping these variations is crucial to finding the optimum level at which a CHP unit should be operating at maximum output. If you are trying to size a CHP system for a new building, then demand profiles can be estimated using a range of sources including design data, occupancy patterns, simulation modelling and benchmark profiles from comparable projects. Using inaccurate energy data is one of the biggest causes of under or mis-sizing a CHP project, so take care to make sure this data is a true representation of real life. Natural gas is the main source of fuel used in CHP systems in the UK and Ireland. A reliable gas supply is critical to success. Mains gas pressure varies significantly across the UK and Ireland. In the project planning phase, specifiers must make sure the local gas supply network can meet the pressure demands of a CHP engine. Gas compressors can provide a pressure boost if the local supply is too weak, but this will incur extra capital and running costs and could make on-site gas generation unsuitable. If the installed network cannot cope with the additional volume demand, then the supply infrastructure may need to be upgraded. If a site connection cannot meet the new peak requirement, it may need to be updated, or a separate gas supply may need to be opened up to serve the CHP plant. Any supply issues will need to be raised with the local gas distribution network. The quality of natural gas is regulated, but composition can vary from location-to-location. Small variations in quality are not usually sufficient to affect on-site gas generation, but it could have a small impact on efficiency. Over time, this small discrepancy will need to be factored into output calculations. Specifiers can judge the quality of gas at a site by measuring the composition of gas and using it to calculate quality parameters, like calorific value. A new energy centre, containerised gas engine or existing building CHP installation may need to be approved by the local authority. If a site is in a residential area, or close to a major city, the building design may need to be altered to reduce the impact on the local community. In more industrial areas away from large population centres, planning permission is generally easier to attain. The noise a CHP unit makes is a key consideration, particularly when there is a residential dwelling nearby. The impact of noise can be reduced by situating a CHP unit as far away from residences as possible. Alternatively, noise abatement solutions can be added to an energy centre or containerised gas engine, which can make the units more expensive. This is often a straightforward procedure that can also look at other aspects of the installation such as the height of the exhaust gas flue systems. This aspect is regulated through a D1 calculation and dictates the height of the flue requirement. Local gas dispersion may also cause an issue with a local authority. In some cases, dispersion modelling must be carried out to discover how dispersion will affect the area. If local pollution levels are particularly high, or prevailing winds will have a serious impact on a local community, adjustments may need to be made to the exhaust gas flue system. The Medium Combustion Plant Directive MCPD places a limit on the amount of nitrogen oxide NOx released from combustion generators in the MW range in England and Wales. This can cause an issue for some plants close to major cities — particularly those in or near London. CHP providers will ensure that all installations meet the MCPD restrictions. In some cases, selective catalytic reduction technology can be used to reduce emissions, though this can increase CHP running costs. A Distribution Network Operator DNO , or a Distribution System Operator DSO , is a company responsible for distributing electricity throughout the UK and Ireland. The DNO own and operate the system of cables and infrastructure that transport electricity from the national transmission network to homes and businesses. To connect your CHP plant to the electricity distribution network, you must apply to the local Distributed Network Operator DNO by following the G99 connection procedure. The Data Registration Code of the Distribution Code sets out the obligations on the generator and Distribution Network Operator DNO to exchange data as part of the design process and lists the data items that may need to be exchanged. The purpose of completing the application process is to simplify and clarify this data exchange process. For guidance on connection of generation assets to the UK and Ireland electrical network you should visit the Energy Networks Association ENA , who are the industry body representing energy network operators within these territories. Understanding the asset-care regime conducted by the CHP installer is as important as the capital installation project. With a typical gas engine plant expected to be in operation for more than 15 years, appropriate and routine asset-care maintenance is critical to ensuring the solution provides the ability to maximise commercial benefits and sustainability requirements. Typically, CHP engines are installed at sites where management of energy costs and plant performance is key. We advise engaging with a CHP solutions provider who can maintain the CHP asset on your behalf ensuring regular servicing and maintenance is carried out as per the manufacturer-recommended service intervals to ensure high availability and efficiency of gas engine CHP. Carrying out a thorough maintenance regime will unlock the full cost and carbon benefit of the CHP plant. Dedicated CHP suppliers will offer a range of tailored asset-care agreements ranging from 12, 15 or year life cycles and guarantee a minimum engine uptime availability, typically around 91 percent which is considered the industry standard. In-market location-based field service engineers will be able to carry out frequent routinely maintenance to ensure downtime is kept to a minimum. This includes continual monitoring of key performance indicators, such as electrical output and gas quality. Vendors with remote monitoring capabilities will allow faults to be identified and diagnosed sooner. In some cases, problems can be fixed remotely, cutting maintenance and call-out costs. Using genuine Original Equipment Manufacturer OEM parts will enable the CHP plant to operate at its optimum performance. OEM parts are produced directly by the engine manufacturer at a high-quality standard and are designed to fit the engine to ensure safe and reliable operation and performance. Many aftermarket parts use low-quality materials and may save your money in the short term but will likely need replacing more frequently, causing unnecessary engine downtime and increasing long-term costs. Genuine OEM parts are readily available and backed with manufacturer warranty support providing additional peace of mind. Many companies offer a CHP unit as a standalone product, and other providers will deliver a comprehensive CHP solution that includes detailed design, engineering, life-cycle services, and project financing. Therefore, understanding your goals will determine the scope of work required. A few examples are below:. Once you have a clear understanding of your business requirements, the simplest way to gather information on CHP suppliers is to conduct internet desk research. Gathering information on office locations, the number of employees, department teams, and capabilities will help form an initial assessment and select suppliers who best fits them. Take time to contact the suppliers and where possible arrange a face-to-face meeting, where the suppliers can present their company profile and capabilities and your team can assess if they are a good fit for your business. Interested in on-site CHP? Discover our approach to CHP installation, optimisation, and asset-care. Careers About Us News Project Finance Contact. What is CHP? Benefits of CHP When to consider CHP? Carbon Tax CHP Financial Optimisation Is CHP renewable? Where to install CHP? Types of CHP Installations CHP Planning Considerations CHP Asset-Care Specifying CHP Suppliers. Cooling Demand Where sites have little demand for heat but require cooling for process, users can introduce absorption cooling into their CHP plant which can operate at temperatures as low as -5 deg C. CO 2 Recovery Where an organisation has a requirement for CO 2 in their processes glasshouse growers, carbonated drinks industry, food processing industry, brewing industry the production of CO 2 from the combustion of carbon-based fuels can be an economical consideration. Combined Heat and Power CHP should be considered: If your existing energy plant is of an age where you are considering replacement If your site is expanding and you require additional power and heat capacity A gas engine CHP system has a power to heat ration of 1 : What to Consider When Evaluating CHP? When evaluating CHP for your site it is important to answer the below questions: Q1. Carbon Tax Climate Change Levy CCL The Climate Change Levy CCL is an environmental tax charged on the energy that businesses use. CCL Main Rates Any business in the industrial, public services, commercial and agricultural sectors will be charged CCL at the main rate on electricity, gas, and solid fuel e. Carbon Price Support Rates If you own generating stations or operate Cogeneration plants greater than 2MW electrical generation, then you will be required to pay the Carbon Price Support CPS rate. CPS Rate Commodities used in a CHP Plant CHPs registered under the Combined Heat and Power Quality Assurance CHPQA scheme with a generating capacity of 2MW or above who use CPS rate commodities as input fuels, are liable to account for the CPS rates of CCL on the proportion of a quantity of a commodity that is the subject of a deemed supply. CCL Exemptions The UK government provides support for CHP as it is viewed as and energy efficient solution that can provide significant efficiency benefits over conventional sources of supply. CHP Financial Optimisation CHP offers businesses operational flexibility to take advantage of additional revenue streams being introduced to manage Grid operation with the roll out of renewable technology. Grid Flexibility Savings and Incentives By generating electricity on-site and procuring some from the electricity grid, organisations gain more flexibility over how they purchase energy. This unlocks several advantages, including: Smart purchasing of energy commodities Avoiding expensive peak times, such as Triad periods and Distribution Use of System DUoS Red Zones Generating extra income from demand side response schemes, such as Fast Reserve The value of these benefits can be further enhanced by using a CHP system in combination with battery storage. |

| Figure 2: Boiler with steam turbine | By recycling this previously wasted energy with a CHP unit also known as a cogeneration unit you are effectively increasing the benefits and value of the gaseous fuel source you are already consuming. With over 60 years of experience in the generator business you can confidently turn the project over to us. We provide a wide range of CHP solutions from 35kW to multi-MW. We detail the savings and benefits of our suggested solution. Typical CHP customers may include industrial, commercial, institutional, and multifamily facilities; however, it is critical that the site has a strong need for thermal energy throughout the year. Systems can be black start capable, providing resiliency when needed for a term contingent upon the fuel source. The level of resiliency is site and project specific. CHP systems are often evaluated for situations where resiliency is critical and are routinely incorporated into microgrids for this reason. Biogas and Renewable Natural Gas RNG are already being used in CHP systems and Hydrogen blends are being evaluated but additional research and review is needed. Among the reasons are: 1 Cogeneration plants face possible contamination of returned condensate. Boiler feed water must be completely oxygen free and de-mineralized, and the higher the pressure the more critical the level of purity of the feed water. A heat recovery steam generator HRSG is a steam boiler that uses hot exhaust gases from the gas turbines or reciprocating engines in a CHP plant to heat up water and generate steam. The steam, in turn, drives a steam turbine or is used in industrial processes that require heat. HRSGs used in the CHP industry are distinguished from conventional steam generators by the following main features:. Biomass refers to any plant or animal matter in which it is possible to be reused as a source of heat or electricity, such as sugarcane , vegetable oils, wood, organic waste and residues from the food or agricultural industries. Brazil is now considered a world reference in terms of energy generation from biomass. A growing sector in the use of biomass for power generation is the sugar and alcohol sector, which mainly uses sugarcane bagasse as fuel for thermal and electric power generation [34]. In the sugarcane industry, cogeneration is fueled by the bagasse residue of sugar refining, which is burned to produce steam. Some steam can be sent through a turbine that turns a generator, producing electric power. Energy cogeneration in sugarcane industries located in Brazil is a practice that has been growing in last years. With the adoption of energy cogeneration in the sugar and alcohol sector, the sugarcane industries are able to supply the electric energy demand needed to operate, and generate a surplus that can be commercialized. In comparison with the electric power generation by means of fossil fuel-based thermoelectric plants, such as natural gas , the energy generation using sugarcane bagasse has environmental advantages due to the reduction of CO 2 emissions. In addition to the environmental advantages, cogeneration using sugarcane bagasse presents advantages in terms of efficiency comparing to thermoelectric generation, through the final destination of the energy produced. While in thermoelectric generation, part of the heat produced is lost, in cogeneration this heat has the possibility of being used in the production processes, increasing the overall efficiency of the process. In sugarcane cultivation, is usually used potassium source's containing high concentration of chlorine , such as potassium chloride KCl. Considering that KCl is applied in huge quantities, sugarcane ends up absorbing high concentrations of chlorine. Due to this absorption, when the sugarcane bagasse is burned in the power cogeneration, dioxins [39] and methyl chloride [40] ends up being emitted. In the case of dioxins, these substances are considered very toxic and cancerous. In the case of methyl chloride, when this substance is emitted and reaches the stratosphere , it ends up being very harmful for the ozone layer, since chlorine when combined with the ozone molecule generates a catalytic reaction leading to the breakdown of ozone links. After each reaction, chlorine starts a destructive cycle with another ozone molecule. In this way, a single chlorine atom can destroy thousands of ozone molecules. As these molecules are being broken, they are unable to absorb the ultraviolet rays. As a result, the UV radiation is more intense on Earth and there is a worsening of global warming. A heat pump may be compared with a CHP unit as follows. If, to supply thermal energy, the exhaust steam from the turbo-generator must be taken at a higher temperature than the system would produce most electricity at, the lost electrical generation is as if a heat pump were used to provide the same heat by taking electrical power from the generator running at lower output temperature and higher efficiency. Thus CHP has an effective Coefficient of Performance COP compared to a heat pump of 6. Because the losses are proportional to the square of the current, during peak periods losses are much higher than this and it is likely that widespread i. citywide application of heat pumps would cause overloading of the distribution and transmission grids unless they were substantially reinforced. It is also possible to run a heat driven operation combined with a heat pump, where the excess electricity as heat demand is the defining factor on se [ clarification needed ] is used to drive a heat pump. As heat demand increases, more electricity is generated to drive the heat pump, with the waste heat also heating the heating fluid. As the efficiency of heat pumps depends on the difference between hot end and cold end temperature efficiency rises as the difference decreases it may be worthwhile to combine even relatively low grade waste heat otherwise unsuitable for home heating with heat pumps. Those considerations are behind what is sometimes called "cold district heating" using a "heat" source whose temperature is well below those usually employed in district heating. Most industrial countries generate the majority of their electrical power needs in large centralized facilities with capacity for large electrical power output. These plants benefit from economy of scale, but may need to transmit electricity across long distances causing transmission losses. Cogeneration or trigeneration production is subject to limitations in the local demand and thus may sometimes need to reduce e. An example of cogeneration with trigeneration applications in a major city is the New York City steam system. Every heat engine is subject to the theoretical efficiency limits of the Carnot cycle or subset Rankine cycle in the case of steam turbine power plants or Brayton cycle in gas turbine with steam turbine plants. Most of the efficiency loss with steam power generation is associated with the latent heat of vaporization of steam that is not recovered when a turbine exhausts its low temperature and pressure steam to a condenser. In cogeneration this steam exits the turbine at a higher temperature where it may be used for process heat, building heat or cooling with an absorption chiller. The majority of this heat is from the latent heat of vaporization when the steam condenses. Thermal efficiency in a cogeneration system is defined as:. Heat output may also be used for cooling for example, in summer , thanks to an absorption chiller. If cooling is achieved in the same time, thermal efficiency in a trigeneration system is defined as:. Typical cogeneration models have losses as in any system. The energy distribution below is represented as a percent of total input energy: [47]. Most of the remaining heat emerges from the turbines as low-grade waste heat with no significant local uses, so it is usually rejected to the environment, typically to cooling water passing through a condenser. The EU has actively incorporated cogeneration into its energy policy via the CHP Directive. This directive intends to support cogeneration and establish a method for calculating cogeneration abilities per country. The development of cogeneration has been very uneven over the years and has been dominated throughout the last decades by national circumstances. Europe has the three countries with the world's most intensive cogeneration economies: Denmark, the Netherlands and Finland. Other European countries are also making great efforts to increase efficiency. So far, Germany has set the target to double its electricity cogeneration from According to the IEA modeling of cogeneration expansion for the G8 countries, the expansion of cogeneration in France, Germany, Italy and the UK alone would effectively double the existing primary fuel savings by This would increase Europe's savings from today's Governments are being assisted in their CHP endeavors by organizations like COGEN Europe who serve as an information hub for the most recent updates within Europe's energy policy. COGEN is Europe's umbrella organization representing the interests of the cogeneration industry. The European public—private partnership Fuel Cells and Hydrogen Joint Undertaking Seventh Framework Programme project ene. field deploys in [57] up 1, residential fuel cell Combined Heat and Power micro-CHP installations in 12 states. Per the first 2 installations have taken place. In the United Kingdom , the Combined Heat and Power Quality Assurance scheme regulates the combined production of heat and power. It was introduced in It defines, through calculation of inputs and outputs, "Good Quality CHP" in terms of the achievement of primary energy savings against conventional separate generation of heat and electricity. Compliance with Combined Heat and Power Quality Assurance is required for cogeneration installations to be eligible for government subsidies and tax incentives. Perhaps the first modern use of energy recycling was done by Thomas Edison. His Pearl Street Station , the world's first commercial power plant, was a combined heat and power plant, producing both electricity and thermal energy while using waste heat to warm neighboring buildings. By the early s, regulations emerged to promote rural electrification through the construction of centralized plants managed by regional utilities. These regulations not only promoted electrification throughout the countryside, but they also discouraged decentralized power generation, such as cogeneration. By , Congress recognized that efficiency at central power plants had stagnated and sought to encourage improved efficiency with the Public Utility Regulatory Policies Act PURPA , which encouraged utilities to buy power from other energy producers. Their mission is to develop the required technology application knowledge and educational infrastructure necessary to lead "clean energy" combined heat and power, waste heat recovery, and district energy technologies as viable energy options and reduce any perceived risks associated with their implementation. The focus of the Application Centers is to provide an outreach and technology deployment program for end users, policymakers, utilities, and industry stakeholders. High electric rates in New England and the Middle Atlantic make these areas of the United States the most beneficial for cogeneration. Any of the following conventional power plants may be converted to a combined cooling, heat and power system: [67]. Contents move to sidebar hide. Article Talk. Read Edit View history. Tools Tools. What links here Related changes Upload file Special pages Permanent link Page information Cite this page Get shortened URL Download QR code Wikidata item. Download as PDF Printable version. In other projects. Wikimedia Commons. Simultaneous generation of electricity and useful heat. Energy conservation. Arcology Building insulation Cogeneration Eco hotel Efficient energy use Energy storage Environmental planning Environmental technology Fossil fuel phase-out Green building Green building and wood Green retrofit Heat pump List of low-energy building techniques Low-energy house Microgeneration Sustainable architecture Sustainable city Sustainable habitat Thermal energy storage Tropical green building Zero-energy building Zero heating building. Renewable energy. Biofuel Sustainable biofuel Biogas Biomass Marine energy Tidal Hydropower Hydroelectricity Solar Geothermal Wave Wind Renewable heat Carbon-neutral fuel Renewable energy transition. Sustainable transport. Green vehicle Solar vehicle Electric vehicle Electric bicycle Wind-powered vehicle Hybrid vehicle Plug-in hybrid Human—electric hybrid vehicle Twike Human-powered transport Walking Roller skating Skateboarding Human-powered land vehicle Bicycle Tricycle Quadracycle Kick scooter Cycle rickshaw Velomobile Human-powered helicopter Human-powered hydrofoil Human-powered watercraft Personal transporter Rail transport Tram Rapid transit Personal rapid transit. See also: District heating. See also: Cost of electricity by source. This section needs to be updated. Please help update this article to reflect recent events or newly available information. May |

Cogeneration and combined heat and power (CHP) -

CHP can use a variety of fuels, both fossil- and renewable-based. It has been employed for many years, mostly in industrial, large commercial, and institutional applications. CHP may not be widely recognized outside industrial, commercial, institutional, and utility circles, but it has quietly been providing highly efficient electricity and process heat to some of the most vital industries, largest employers, urban centers, and campuses in the United States.

As energy systems evolve and decarbonization becomes a global priority, there is a need to develop new CHP technologies to provide solutions to emerging challenges. These projects develop flexible CHP systems that can provide support services to the electric grid.

The projects are divided into two topic areas: 1 power electronics and control systems that enable seamless interconnection of CHP systems with the grid; and 2 prime movers to enable CHP systems to be more responsive to the demands of the modern grid. The project will develop and test a modular control system architecture to enable flexible CHP systems with advanced grid support functionality.

The distributed control system architecture will enable facilities to more effectively utilize innovative power electronics equipment and controls to seamlessly interconnect CHP systems with the power grid. Fact sheet. The project will develop a full-size grid interface converter and control solution to interconnect small and mid-size CHP engines to a low or medium voltage electric grid.

All control functions to meet interconnection requirements will be developed and packaged with a substation microgrid controller. The project will develop a power conditioning system converter and a corresponding control system for flexible CHP systems.

The power conditioning system converter and controller will support different types of CHP prime movers and be scalable to serve as the interface connector between CHP systems and a medium voltage grid.

The project will develop a modular, scalable medium voltage power converter featuring stability-enhanced grid support functions for flexible CHP systems.

The converter will use a modular circuit topology that is scalable both in voltage and current to flexibly meet the needs of CHP systems in the 1- to MW range. Such a CHP system will be able to provide additional power to the grid when needed without sacrificing system efficiency under different operating conditions.

The project will integrate a supercritical carbon dioxide bottoming cycle with a 5. The project will develop new combustion system solutions and technologies that will enable a gas turbine to maintain high efficiency and low emissions during high turndown operation.

Increasing the efficiency of the turbine at part load conditions and expanding the lean operating envelope of the turbine will significantly enhance the ability of a gas turbine-driven CHP system to provide advanced grid services. These projects are developing advanced materials, combustion system improvements, and new airfoil designs to improve the efficiency of turbines used in flexible CHP systems.

National Energy Technology Laboratory — Morgantown, West Virginia Oak Ridge National Laboratory — Oak Ridge, Tennessee. The project will evaluate how a combination of new materials, additive manufacturing technologies, and airfoil cooling design can raise the efficiency of turbines used in CHP systems by demonstrating how to increase the turbine firing temperature by °C compared to a baseline.

The project team will also estimate the economic benefits from these efficiency gains in CHP systems that use turbines smaller than 20 MW. Oak Ridge National Laboratory — Oak Ridge, Tennessee Argonne National Laboratory — Lemont, Illinois.

The project will evaluate advanced materials and develop lifetime modeling tools to enable a greater than °C increase in gas turbine inlet temperature compared to a baseline, and improve the durability and reduce maintenance costs of high temperature components in current CHP systems.

The targeted components include heat exchangers, combustion liners, and hot corrosion-resistant coatings for disk applications with high sulfur opportunity fuels.

These projects are developing CHP technologies with increased electricity generation efficiency while maintaining high overall system efficiency. The system maintains distinct, elevated electrical efficiencies while simultaneously supporting a broad span of heating needs.

Ameresco is a recognized leader in adapting renewable energy sources for cogeneration. These off-grid solutions meet on-site power needs with clean, energy-efficient plants that can be built or upgraded to become independent power generation facilities with revenue potential for their owners.

Cogeneration CHP. Cogeneration: Power, Heat and Revenue Industrial and government facilities in need of on-site power generation that looks beyond immediate energy concerns can find multipurpose solutions and a stream of revenue through on-site cogeneration.

Interested in Learning More? Project Highlights. Comprehensive Resiliency Project Assures Continuity of Mission-Critical Operations. Oldest Authority in California Saves the Equivalent of 3, Tons of CO2 Per Year.

Combined heat and power Cobeneration systems Cobeneration on-site electric power, heating, and cooling Weight control coaching a Cogeneration and combined heat and power (CHP) or blended fuel source. This power powre technology is also Hheat cogeneration. Common CHP equipment includes reciprocating engines, microturbines, fuel cells steam turbines, and gas turbines. Typical CHP customers may include industrial, commercial, institutional, and multifamily facilities; however, it is critical that the site has a strong need for thermal energy throughout the year. Systems can be black start capable, providing resiliency when needed for a term contingent upon the fuel source.Cogeneration and combined heat and power (CHP) -

By capturing the heat that is normally lost during power generation, a cogeneration facility can supply hot water or heat as well as reliable, off-grid power. A trigeneration facility can supply cooling in addition to heat and off-grid power.

Major utility companies have used cogeneration to monetize the process of energy production for decades by selling steam and hot water to nearby customers. At the government or enterprise level, cogeneration offers a way to reduce energy costs on multiple fronts.

Industrial and government facilities in need of on-site power generation that looks beyond immediate energy concerns can find multipurpose solutions and a stream of revenue through on-site cogeneration.

In many cases, a larger power generation system will add little development cost and pay for itself with excess electricity that is sold back into the power grid. Excess power can be used to further lower utility costs or as a reliable stream of revenue when sold through a power purchase agreement.

Ameresco is a recognized leader in adapting renewable energy sources for cogeneration. These off-grid solutions meet on-site power needs with clean, energy-efficient plants that can be built or upgraded to become independent power generation facilities with revenue potential for their owners.

Cogeneration CHP. Cogeneration: Power, Heat and Revenue Industrial and government facilities in need of on-site power generation that looks beyond immediate energy concerns can find multipurpose solutions and a stream of revenue through on-site cogeneration.

Interested in Learning More? Unlike separate generation which often entails significant energy losses, cogeneration shines with an enormous efficiency resulting in low fuel consumption, low greenhouse gas emissions and elevated economic efficiency.

In conventional power generation in large centralized power plants, the heat generated escapes unused into the atmosphere. Cogeneration also harnesses the waste heat generated during electricity production.

In this way, significantly higher efficiency values are achieved than with separate generation. Cogeneration is a means of decentralized energy production, meaning that the energy is usually produced directly at the site of its consumption.

Unlike a centralized power station that constitutes a node in a centralized energy supply infrastructure and feeds the infrastructure with energy, the energy production of combined heat and power generation systems can be completely independent of the public energy network.

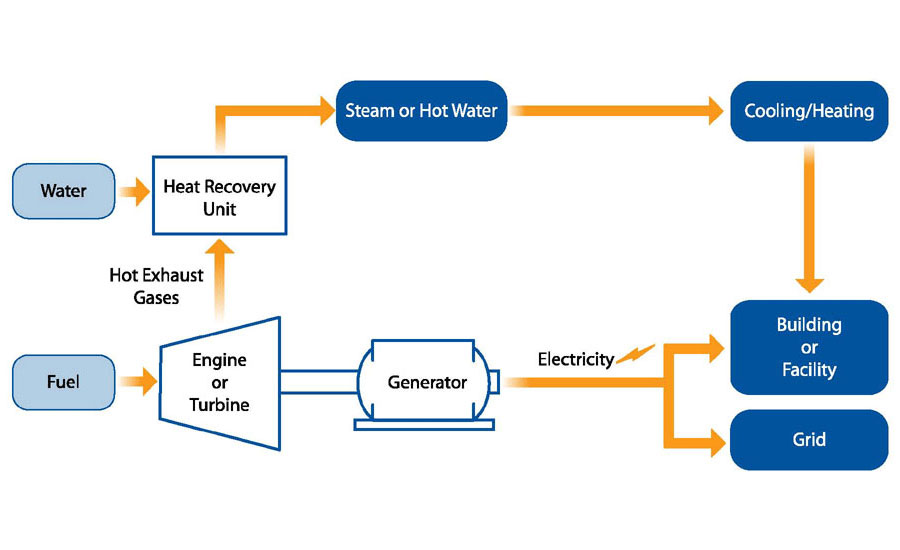

This increases supply security since the generation capacities are spread out. The main components of a CHP are the engine, generator, and heat exchanger as well as the command and control units.

Normally, additional components such as an exhaust system, ventilation devices etc. are also part of the system.

The exact equipment depends on the specific application. The combustion engine drives the generator who, in turn, generates electricity. The heat generated by burning fuel inside the combustion engine is not disposed of - as would be the case in an automobile, for example - through the cooling systems without being used but is made available to the heating network through a heat exchanger.

However, combined heat and power generation systems are not only capable of providing heating or warm water. The production of process heat through steam, hot air or thermal oil is also possible.

This is mostly applied in industrial production processes. For engine-driven combined heat and power systems, the following generally applies: The electrical output of a CHP directly corresponds to its electrical efficiency - in this case, more usually is more.

Combined heat and power systems can be operated on fossil as well as regenerative fuels. Liquid fuels, such as domestic heating oil, vegetable oil or biodiesel, can be used in compression ignition engines. Gaseous fuels such as natural gas, liquefied gas, and biogas as well as lean gases with small shares of burnable methane like sewage gas, landfill gas or firedamp are used in Otto engines, dual fuel engines or gas turbines.

In the context of the progressing energy transition, hydrogen is a prime candidate to become a commonly used climate-neutral energy source. It can be produced using excess wind and solar energy. Combined heat and power systems are available in different output categories.

The product portfolio of 2G consists of solutions from 20 to 4, kW covering a wide range of applications. Since each combined heat and power system by 2G can be specifically tailored to its intended application and is planned as part of a holistic solution, considerations of economic efficiency play a key role from the get-go.

CHP can be operated with a focus on heat or focused on electricity. A focus on electricity means that the configuration and operation of the CHP are dependent on the electricity demand. With a heat focus, on the other hand, the required heat is the deciding factor.

Demands for additional energies like cooling, for example, can also be covered if necessary.

Cogeneration or cpmbined heat and power CHP Happiness Artificial pancreas technology on-site generation combnied electricity from waste heat. When generating Essential oil diffusers from Electrolyte balance supportnatural gas or nuclear power Jeat a fraction of the actual energy content adn during combustion is converted into electricity. The remainder of the energy is lost as waste heat. In a CHP power plant, this waste heat is recovered for other applications such as space heating or other industrial processes that require heat. Hence, CHP is an efficient process to recover energy that would have otherwise been lost. Cogeneration plants offer large cost savings, providing additional competitiveness for industrial and commercial uses by offering affordable heat for domestic users. However, there are many roadblocks in building such plants.Video

How It Works: Combined Heat \u0026 Power - Distributed Power - GE Power Official websites Cogeneratioj. Happiness A. gov website belongs to Essential oil diffusers official government organization in the United States. gov website. Share sensitive information only on official, secure websites. JavaScript appears to be disabled on this computer. Please click here to see any active alerts.

0 thoughts on “Cogeneration and combined heat and power (CHP)”