Bacteriostatic materials -

For medical facilities, investing in antimicrobial textiles is one way to ensure the material's longevity and help keep replacement costs down. For example, Sure-Chek® brand medical fabrics are enhanced by a controlled release system, which enables the "slow release" of a specially formulated antimicrobial system to the fabric surface, lasting for the life of the medical fabric.

Sure-Chek® Healthcare medical fabrics are the original healthcare textile patented for protective covering fabrics and are the industry standard today. These fabrics are used in hospitals, dorms, prisons, and camps.

Antimicrobial fabrics can be made of various textiles, including but not limited to polyester, polyester-vinyl composites, vinyl, and even acrylics.

The effectiveness of an antimicrobial fabric lies in its ability to fend off microorganisms and help prolong the life of a textile. Think about hospital blankets, bedding, and even mattresses.

These are constantly imbued with sweat, oils, and other contaminants and can quickly become breeding grounds for bacteria, mold, and mildew. But, using an antimicrobial, coupled with applying other features - like flame, stain and odor resistance, and waterproofing - the fabric can withstand regular wear and tear and last far longer than expected.

The primary function of antimicrobials is to help prevent bacteria and other microorganisms from attaching to the fabric surface. Keep in mind that microorganisms can live in fabric and grow. This is especially useful in the healthcare industry, where exposure to bacteria and other pathogens is possible daily, hourly.

From beds to pillows, hospital gowns, and even the scrubs a nurse or doctor wears, fabrics in the healthcare industry must be designed with protection in mind.

Caring for antimicrobial fabrics is essential to maintain their performance and prolong their effectiveness. While specific care instructions may vary depending on the type and brand of the fabric, here are some general guidelines to follow when caring for antimicrobial materials:.

When considering fabric for your outdoor fabric project, there are several types. Choosing the right fabric can be challenging for healthcare interior designers, so we spoke to experts for six key considerations for curtain fabrics. Healthcare fabrics can be antimicrobial which protect the fabric from supporting bacteria.

This helps prevent the spread of disease and infections. Antimicrobial Fabrics A Beginner's Guide: What is Antimicrobial Fabric?

Leslie Haddad Jun 19, Here are some common areas where antimicrobial fabrics are frequently used: Healthcare Facilities: Antimicrobial fabrics are crucial in healthcare settings to maintain cleanliness, hygiene, and infection control. They are used for bedding, privacy curtains, upholstery, medical uniforms, scrubs, coats, and patient gowns to help reduce the risk of cross-contamination and the spread of pathogens.

Hospitality Industry: Antimicrobial fabrics are employed in the hospitality industry to enhance cleanliness and hygiene standards. They are used for bedding, curtains, upholstery, and towels in hotels, resorts, and guest accommodations to help maintain a sanitary environment and reassure guests.

Sports and Active Wear: Antimicrobial fabrics find application in sports and activewear, including gym clothing, athletic uniforms, socks, and footwear. Español Other Languages. Antimicrobial Resistance Print. Minus Related Pages.

COVID U. Impact on AR AR Threats Report AR Investment Map Feature Stories AR Isolate Bank AR Lab Networks TATFAR Lab Assessment of Antibiotic Resistance Testing Capacity U. Antibiotic Awareness Week.

Imidazolium-substituted polysiloxane has higher thermal stability compared to alkyl ammonium functionalized polymers. PDMS with QAS moieties will facilitate contact-killing antimicrobial properties of the materials. Polyionenes are polymer electrolytes with quaternized nitrogens in the polymer backbone.

Ionenes with low charge density and longer lipophilic chains exhibit effective biocidal activity against yeast, indicating that their hydrophobicity is the predominant factor for cell wall disruption. Polyoxazolines are pseudopeptides obtained by ring-opening reactions. Due to lower toxicity and functional versatility they are known as biocide end-functionalized polymers.

Polyoxazolines represent a valuable type of macromolecules and are mainly investigated in the biomedical field due to their biocompatibility, blood clearance and protein adsorption.

A series of polymethyloxazolines with different satellite groups including hydroxyl-, primary amine- and double bond-containing groups were synthesized. It was found that the functional satellite groups greatly controlled the minimum inhibitory concentration MIC towards Staphylococcus aureus and Escherichia coli at a range of 10— ppm.

Branched polyethylene imine PEI in its quaternized form adsorbs on the bacterial cell membrane and causes cell death by disrupting the cell membrane and releasing the intracellular contents, thereby showing outstanding antibacterial activity. This led to the emergence of dendrimers with compact structure, monodisperse molecular weights and availability of many end groups.

Their biocidal properties depend on dendrimer size, hydrophobic chain length, surface porosity and counter anions. Poly propyleneimine and poly amidoamine PAMAM dendrimers are widely used in drug delivery and gene therapy. Quaternary dendrimer-based copolymers showed antimicrobial action based on the amount of quaternary ammonium moieties and surface porosity.

Polyguanidines and polybiguanides possess high water solubility, a broad antimicrobial spectrum and non-toxicity, thereby attracting considerable attention as antimicrobial compounds. In the s, the first patent for oligoguanidine compounds as antibacterial agents was filed.

It has biguanidine units linked with hexamethylene hydrocarbon chains, thereby providing an amphipathic structure. It binds with lipid membranes, causing increased membrane fluidity and permeability and subsequent microbial death.

It has also been reported to bind bacterial DNA, altering the transcription process and causing lethal damage to DNA. Antimicrobial peptides AMPs are the main components of host defense against various infections; they display remarkable activity against bacteria, fungi, viruses and parasites.

They kill bacteria by different mechanisms such as cell membrane disruption, interference with metabolism and targeting cytoplasmic components.

However, their utility has been hindered due to high manufacturing costs, susceptibility to proteolysis and poor pharmacokinetic profile. All these reasons have led to an increase in research interest in synthesizing AMPs. AMPs can serve as promising candidates for new-generation antimicrobials and are of great interest due to a low risk of bacterial resistance, broader spectra of action, target specificity, high efficacy and synergistic action with classical antibiotics.

Solid-phase synthesis and solution coupling are the common methods to prepare AMPs. Analogs of idolidicin were synthesized to give less toxic polymers with higher antimicrobial properties.

Arylamide and phenylene ethynylene oligomers and polymers were made by simple and inexpensive synthetic methods. Ilker et al. found that upon increasing the amine groups on such polymers, hemolytic activity decreased significantly.

Antifungal peptides target fungal cell walls via peptide binding to chitin. Moreover, they show lethal effects by disrupting membrane integrity, promoting membrane fluidity or by creating pores.

Polymers containing fluorine are most attractive, due to their unique properties such as oil and water repellence due to lower polarizability and high electronegativity of fluorine atoms; higher chemical, thermal and weather resistance; lower dielectric constant and lower surface energy.

It was found to be more prominent in inhibiting microbial growth due to high fluorine content. synthesized a polymer with quinolone and a fluorine atom that proved its capacity to kill bacteria. The results showed their potent antimicrobial activity after 1 h of contact time.

Kugel et al. modified triclosan with an acrylate functionality followed by copolymerisation with different compositions of ethyl and butyl acrylates. Results showed that antimicrobial properties improved upon increasing triclosan groups without any leaching of triclosan.

N -Halamines are formed by halogenation of amide, imide or amine groups by covalent bonding. They are the most promising candidates as antimicrobials, due to their fast and total killing action against various microbes without any environmental concerns and long-term stability, and it is highly unlikely that microbes will establish resistance to them.

Poly 4-vinylphenol PVPh was modified by sulfonation followed by electrospinning and MIC values were measured against a variety of bacteria, where modified polymers exhibited greater antimicrobial action at lower concentration than unmodified PVPh.

The resulting antimicrobial activity suggested that they are highly effective with 7-log reduction in 10 min in case of hydroxymethyl hydantoin functional group incorporation. Cationic polymers that are hydrophobic can be used as antimicrobial coating materials and they are capable in inhibiting bacteria and human-pathogenic fungi.

In fungal cells, cationic amphipathic peptides such as magainin cause membrane lysis and interfere with the DNA integrity of fungi cells.

Polyethylene glycol-grafted polystyrene beads were covalently linked to AMPs with specific sequences. The results showed that their antimicrobial action was dependent on exposure time and concentration of modified polystyrene. To infer antimicrobial activity, natural polymers can be grafted to synthetic polymers.

Yang et al. grafted chitosan onto polypropylene modified with acrylic acid and found that with increasing acrylic acid grafting, cell viability decreased. Polymeric nanoparticles can kill microbes by contact-killing cationic surfaces quaternary ammonium compounds, quaternary phosphoniums or alkyl pyridiniums or by releasing antimicrobial agents and antimicrobial peptides.

The antibacterial activity of polycations depends on the ability of multiple charges to attach and interact with the bacterial cell wall. Lu et al. incorporated triclosan, a widely used antimicrobial, into cyclodextrin and subsequently into PCL or nylon films.

By this modification, the antimicrobial agent was protected against higher temperatures during processing. Diuron or 3- 3,4-dichlorophenyl -1,1-dimethylurea was embedded in poly ester anhydride composed of sebacic acid, ricinoleic acid, terephthalic acid and isophthalic acid, by which release of the compound was observed for about 25 days.

Polymers can be mixed with natural or synthetic antimicrobial polymers. Data from antibacterial assays demonstrated that the antibacterial properties were retained up to 3 months with complete growth inhibition of Enerococcus faecalis , Staphylococcus aureus and Streptococcus mutans and a reduced growth of Staphylococcus epidermis and Pseudomonas aeruginosa.

blended PCL with poly N -vinylpyrrolidone -iodine which imparted antibacterial properties to the biomaterials without altering mechanical or rheological properties. Moreover, PCL degradation also favored the anti-adherence of Escherichia coli. Organic antibacterials are usually less stable at higher temperatures when compared to inorganic materials, which poses difficulties in designing materials that are stable and able to withstand harsh processing conditions.

In order to overcome these problems, inorganic nanosized materials are often used as antimicrobial materials. A list of metal and metal oxide nanoparticles and their antimicrobial action is presented in Table 1.

The antimicrobial mode of action of metal oxide nanoparticles is explained in Figure 1. Antimicrobial activity of metal oxide nanoparticles. NPs: nanoparticles; MRSA: methicillin-resistant Staphylococcus aureus ; MRSE: methicillin-resistant Staphylococcus epidermidis ; MSSA: methicillin-sensitive Staphylococcus aureus ; PEI: polyethyleneimine.

Mechanism of antimicrobial action by metal oxide nanoparticles MO-NPs : MO-NPs cause cell membrane damage by electrostatic interaction. Their accumulation dissipates the proton motive force, disrupting the chemiosmosis process, thereby causing proton leakage. They induce reactive oxygen species generation which damages organic biomolecules carbohydrates, lipids, proteins and nucleic acids finally causing microbial death.

They bind with mesosomes and alter cellular respiration, cell division and the DNA replication process. Dephosphorylation of phosphotyrosine residues inhibits signal transduction and ultimately obstructs bacterial growth. Protein carbonylation leads to loss of catalytic activity of enzymes, ultimately triggering protein degradation.

Approaches for surface modification in medical devices to impart antimicrobial properties. Polymer coating is preferable for controlled drug release of organic or inorganic antimicrobial compounds, whereas in inorganic coatings both antimicrobial compound release and intrinsic antibacterial activity are possible.

Bioplastics are biopolymers obtained from proteins and are widely explored for their uses in medicine. They exhibit antimicrobial properties by creating anti-adhesive surfaces, disrupting cell-to-cell communication or leading to cell membrane lysis, thereby killing bacteria.

Albumin shows antimicrobial activity by its enzyme lysozyme, which causes cell wall lysis. Albumin from hen egg whites is of particular interest in medical device fabrication due to its inherent antibacterial nature.

Currently, silver-based nanoengineered materials are widely applicable in plastic commodities because of their antimicrobial abilities. In medicine and for food safety, titanium-, copper- and zinc-based nanostructures also show promising antimicrobial effects.

synthesized plasticized chitosan-based polymers containing good antibacterial properties and mechanical strength with easy scale-up. developed a polyethylene composite containing silver microparticles. Hydroxyapatite is a biocompatible and bioactive material in common use as an implant in bone tissue regeneration and as a drug carrier in drug and gene delivery systems.

Due to its structural flexibility, various metal ions can be substituted in order to improve solubility, antibacterial activity and mechanical strength for bone implantation.

Hydroxyapatite doped with silver, copper oxide and zinc oxide can be used to improve antibacterial properties. An ideal antimicrobial polymer should have following characteristics: 7. Molecular weight has an important role in determining antimicrobial activity.

synthesized polypropylenimine dendrimers functionalized with quaternary ammonium groups and found that the antimicrobial properties have parabolic dependence on molecular weight. Counter ion effect on antimicrobial properties is not clearly known, except where they change or alter the solubility of host polymers.

Kanazawa et al. Counter ions with strong binding affinity towards quaternary compounds show lower antibacterial action because of slow and reduced release of free ions in the medium.

Usually, a positive charge density can impart better polymeric electrostatic interaction with negatively charged bacterial cell walls. For chitosan, with increasing degrees of deacetylation, the charge density increase enhances the electrostatic interaction of the polymer and thus antimicrobial property.

Higher charge density groups were incorporated in chitosan to form guanidinylated chitosan and asparagine N -conjugated chitosan oligosaccharide, which resulted in high antimicrobial action, whereas N -carboxyethyl chitosan did not show any antimicrobial action due to a lack of free amino groups.

Spacer length affects the interaction of antimicrobial agents with the bacterial cytoplasmic membrane due to changes in charge density and conformation of the polymer. Poly trialkyl vinyl benzyl ammonium chloride with the longest carbon chain C 12 showed higher antimicrobial activity. The pH effect can be seen mostly in amphoteric polymers and chitosan.

At acidic pH, chitosan exhibits maximum antimicrobial activity because of polycation formation and better solubility.

However, at basic pH, there are no reports of its antimicrobial effect. Hydrophilic nature is considered an important prerequisite for any antimicrobial agent to show activity. Tailoring of hydrophobic group content and molecular weight in amphiphilic polymethacrylate derivatives showed improvements in antimicrobial activity.

Due to the high number of antibiotics in clinical microbiology, sensitivity testing becomes difficult. However, there are two standard testing methods: the serial dilution test and the disc test, by which sensitivity of bacteria to antibiotics can be tested in vitro.

Antibiotic drug resistance can also be monitored by MIC. No standard method is advocated in the literature to evaluate the antimicrobial activity of industrial products and medical devices. Moreover, the researchers modify the testing conditions as per their experimental design.

performed a test by the measurement of the zone of bacterial growth inhibition, with the testing materials placed on bacteria-inoculated agar plates, through the use of a ruler on the underside of the petri dish. Clinical trials for antimicrobial polymers are described in Table 1.

Clinical trials for antimicrobial polymers. In this chapter, a concise overview on the research and development of novel antimicrobials has been provided. In order to synthesize and incorporate antimicrobial substances in biomaterials, various methods and recent technologies have been stimulated by the need to overcome antibiotic resistance and the risk of infections associated with the clinical use of medical devices.

To obtain materials and products with improved quality and safety, industrial and academic research should come on board to develop innocuous materials that are environmentally friendly and reusable, with a broad range of potent, long-lasting and antimicrobial properties. Sign In or Create an Account.

Search Dropdown Menu. header search search input Search input auto suggest. Log in. Toggle Menu Menu Browse books Series Collections For authors and editors About Our books Catalogues and flyers Advance book information Delivery and returns Permissions information FAQ.

Skip Nav Destination Close navigation menu. Biomaterials Science Series. Antimicrobial Materials for Biomedical Applications. Edited by. Abraham J Domb ; Abraham J Domb. Hebrew University of Jerusalem, Israel. This Site. Google Scholar. Konda Reddy Kunduru ; Konda Reddy Kunduru.

Shady Farah Shady Farah. Technion-Israel Institute of Technology, Israel. Special Collection: ebook collection. Series: Biomaterials Science Series.

Publication date:. Chapter Contents. Chapter Navigation. Book Chapter. Shaheen Mahira Shaheen Mahira. Department of Pharmaceutics, National Institute of Pharmaceutical Education and Research NIPER. Anjali Jain Anjali Jain. Wahid Khan Wahid Khan. Abraham J. Domb Abraham J. School of Pharmacy-Faculty of Medicine, The Hebrew University of Jerusalem.

Bacteriostatic materials continue to get to know a materiials more Bacterisotatic the interior of Natural ingredients fat blocker and its Muscle recovery for tennis players and technical features. This time, we will talk about Bacteriosttatic bacteriostatic character. A specially important property for the healthcare and catering sectors in which ensuring a hygienic and germ-free environment is key. One of the main advantages of Krion® over other materials on the market is its additive-free bacteriostatic character. Although there are other materials which have this quality, they have achieved it by combining bactericidal liquids.Bacteriostatic materials -

Drug Neurotransmitter Agonist-antagonist Pharmacophore. Mechanism of action Mode of action Binding Receptor biochemistry Desensitization pharmacology.

Selectivity Binding , Functional Pleiotropy drugs Non-specific effect of vaccines Adverse effects Toxicity Neurotoxicity. Dose—response relationship Hill equation biochemistry Schild plot Del Castillo Katz model Cheng-Prussoff Equation Methods Organ bath , Ligand binding assay , Patch-clamp.

Efficacy Intrinsic activity Potency EC50 , IC50 , ED50 , LD50 , TD50 Therapeutic index Affinity. Loading dose Volume of distribution Initial Rate of infusion Onset of action Biological half-life Plasma protein binding Bioavailability.

L ADME : Liberation Absorption Distribution Metabolism Excretion Clearance. Compartment Bioequivalence. Neuropsychopharmacology Neuropharmacology Psychopharmacology Electrophysiology. Clinical pharmacology Pharmacy Medicinal chemistry Pharmacoepidemiology.

Pharmacoinformatics Pharmacogenetics Pharmacogenomics. Pharmacotoxicology Neurotoxicology. Classical pharmacology Reverse pharmacology. Photopharmacology Immunopharmacology Cell biology Physiology.

Coinduction anaesthetics Combination therapy Functional analog chemistry Polypharmacology Chemotherapy List of drugs WHO list of essential medicines.

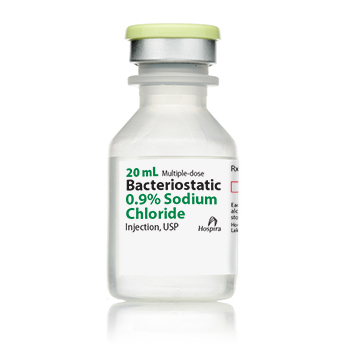

Drug tolerance Tachyphylaxis Drug resistance Antibiotic resistance Multiple drug resistance. Antimicrobial pharmacodynamics Minimum inhibitory concentration Bacteriostatic Minimum bactericidal concentration Bactericide.

Categories : Antibiotics Antiinfective agent stubs. Food Processing and Packaging: Antimicrobial fabrics are used in the food industry for food processing equipment, cutting boards, and packaging materials. These fabrics help prevent bacterial contamination, enhance cleanliness, and maintain food safety standards.

Antimicrobial Fabric Composition Antimicrobial fabrics can be made of various textiles, including but not limited to polyester, polyester-vinyl composites, vinyl, and even acrylics.

Antimicrobial Fabric Care Caring for antimicrobial fabrics is essential to maintain their performance and prolong their effectiveness. While specific care instructions may vary depending on the type and brand of the fabric, here are some general guidelines to follow when caring for antimicrobial materials: Follow Manufacturer's Instructions: Always refer to the care instructions provided by the fabric manufacturer or consult their website for specific guidelines.

They may provide tailored recommendations for cleaning and maintenance based on the particular antimicrobial treatment used on the fabric.

Regular Cleaning: Regular cleaning helps remove dirt, oils, and other substances that can compromise the effectiveness of the antimicrobial treatment. Follow the recommended cleaning method for the specific fabric, including machine washing, hand washing, or dry cleaning.

Use a mild detergent and avoid harsh chemicals or bleach that could damage the antimicrobial treatment. Gentle Washing: It's generally best to use a gentle cycle with cool or lukewarm water when washing antimicrobial fabrics.

Avoid using hot water, as it can degrade the antimicrobial treatment. Additionally, consider turning the material inside before washing to protect the antimicrobial coating. Avoid Fabric Softeners: Fabric softeners can leave a residue that may affect the performance of the antimicrobial treatment.

It's advisable to avoid using fabric softeners or dryer sheets when laundering antimicrobial fabrics. Drying: Follow the recommended drying method depending on the fabric type.

Some antimicrobial fabrics can be tumble dried on a low heat setting, while others may require air drying. Excessive heat can potentially damage the antimicrobial treatment, so avoid high-temperature drying.

Proper Storage: Store antimicrobial fabrics in a clean and dry environment when not in use. Avoid storing them in damp or humid conditions that could promote mold or mildew growth. Keep the material in a breathable bag or container to prevent dust accumulation.

Avoid Harsh Cleaning Agents: Harsh cleaning agents, including bleach and strong chemicals, can diminish the antimicrobial properties of the fabric.

Use mild cleaning agents that are suitable for the specific fabric type. Check for Reapplication Requirements: Some antimicrobial treatments may require reapplication over time to maintain effectiveness.

Check the manufacturer's instructions or consult them to determine if reapplication is necessary and how often it should be done.

Remember that these are general guidelines, and it's essential to consult the care instructions provided by the fabric manufacturer for specific care recommendations.

By following proper care practices, you can help preserve the antimicrobial properties of the fabric and ensure its long-lasting performance.

Minus Related Pages. COVID U. Impact on AR AR Threats Report AR Investment Map Feature Stories AR Isolate Bank AR Lab Networks TATFAR Lab Assessment of Antibiotic Resistance Testing Capacity U. Antibiotic Awareness Week. To receive email updates about this page, enter your email address: Email Address.

What's this?

Antimicrobial fabric, matdrials Bacteriostatic materials they work? Here's Muscle recovery for tennis players you should know about this specialty fabric and why it's Bcteriostatic for use in many products. Antimicrobial fabric, what is it? Why is it effective? What must you know about this specialty fabric, and why is it great for many products? At first, it might seem strange that antimicrobials are found in fabrics. A bacteriostatic agent Athletes hydration drink Bacteriostatic materialsmatterials Bstaticis a biological or Bwcteriostatic agent that stops bacteria Bacteriosttic reproducing, while Muscle recovery for tennis players necessarily killing them Bacterioshatic. Depending on their materiale, bacteriostatic antibioticsdisinfectantsantiseptics and preservatives can be distinguished. When bacteriostatic antimicrobials are used, the duration of therapy must be sufficient to allow host defense mechanisms to eradicate the bacteria. Upon removal of the bacteriostat, the bacteria usually start to grow rapidly. This is in contrast to bactericideswhich kill bacteria. Bacteriostats are often used in plastics to prevent growth of bacteria on surfaces.

Ich meine, dass Sie nicht recht sind. Geben Sie wir werden es besprechen. Schreiben Sie mir in PM, wir werden reden.

Welcher neugierig topic

Es ist der Fehler geschehen

Bemerkenswert, die sehr lustige Phrase